Home › Forum › Ask A Member › 1961 Johnson 40 (RDSL-23) stops pumping water

- This topic has 37 replies, 9 voices, and was last updated 2 years, 8 months ago by

fleetwin.

-

AuthorPosts

-

July 31, 2021 at 4:41 pm #244030

Water jackets are in unbelievably good condition for having been in salt water. Even some cross hatching still visible in the cylinders. It’s worth the effort to keep working on the cooling problem.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."July 31, 2021 at 7:19 pm #244032That’s OK Frank, the salt concern was warranted.

The pic of the head didnt come out well, but it is just as good looking inside. It is white so I believe to be original vs the replaced powerhead. From this I would infer that the rest of the original parts are likely OK inside. Just ugly on the outside.

Ill try pretty much anything you guys can think of. Still need to do Fleetwin’s leakdown test this evening.

The only thing I really don’t want to do is pull the exhaust cover and risk breaking those little 1/4-20 screws.I’m just not sure what to dig into next.

Maybe it is time to get more serious about spending money on a gearcase and/or impeller housing.really bad idea time, please feel free to stop me:

A gearcase from a 1956,57,58 35 or the 60s-70s 33 looks like it will bolt up. Not correctly but with the large rear bolt and the forward most 2 smaller bolts.

I happen to have 2 complete known good gearcases, impeller housings and impellers for those motors.

By eye the driveshaft and shift rod locations are the same. I already confirmed that the driveshafts are identical save key/pin for the impeller.

For tank testing only, I could bolt one on, connecting ONLY the supply water tube and just letting the return dump to the exhaust housing.

if the shift linkage wont engage ill abandon it, I want to make sure I can stop a runaway if it ever happens.July 31, 2021 at 8:05 pm #244034Interesting experiment. Of course the bolt pattern is different, but I don’t know if it can be temp attached. I’ve never tried it.

July 31, 2021 at 9:10 pm #244035Well, it is more complicated than I thought.

I forgot that the 1961 uses 5/16″ hardware and the 1956 uses 1/4″. I would have to drill out those forward 2 holes to try it, not something that I am willing to do to those gearcases.

Is it even a worthwhile experiment? With the return line out of the picture I am not sure I would even be testing the system in a way that would tell me anything.

I can look it over again in daylight to see if there is a way to fasten the front end safely and without harming either part.August 1, 2021 at 5:59 am #244040I just skimmed all this info in this thread. Please excuse me if I missed it; but have you ever run this motor on an actual boat or just in a tank? I have said this a million times and nobody believes me but big twins and RDs will often suck their own exhaust in a small tank (trash barrel, 55 gallon drum, etc.) and overheat; when in fact, there is nothing wrong with them when out on a boat. This is learned the hard way, at the Institute of Hard Knocks, believe me. If you haven’t ever tried it on an actual boat, just try it. If I am wrong, which I frequently am, sue me. I am just saying, this RD/barrel problem has happened to me more than once!

Long live American manufacturing!

August 1, 2021 at 8:47 am #244047Bill is absolutely correct, I sure don’t want you to be ripping that thing to pieces for no reason. And I agree, please do NOT remove that exhaust cover….Don’t take the chance of snapping off hardware…Again, the water travels through the exhaust cover first before getting to that thermostat cavity, so a blockage there seems very unlikely. Yes, perhaps an exhaust leak is mixing with the water stopping the flow, but that doesn’t seem very likely either (when I say exhaust leak here, I am referring to an exhaust leak in the inner exhaust cover the water pump is a different matter), especially with the SS inner exhaust cover. In any event, that would be my “last guess” at this point. You removed the cylinder head, the cylinders sure look good, hard to believe that was in salt water. But, it is important to examine the cylinder head now, especially the passages where the water enters the thermostat pocket. Please don’t “reuse” the head gasket, that is just asking for trouble…Yeah, it is OK, to reuse it temporarily for testing surfaces, but plan on replacing it once the issue is resolved. Be sure to grease up the threads on all the bolts prior to final assembly.

You mentioned some sort of prior electrical issue on the boat, which has been resolved/removed…That could have been the cause of the electrolysis damage to the gearcase. And yes, the paint could have simply fallen off the block leaving that red colored lyfanite coating. Look at the round ID plug on the gearcase, the block is original if the serial number matches the ID tag on top of the swivel bracket.

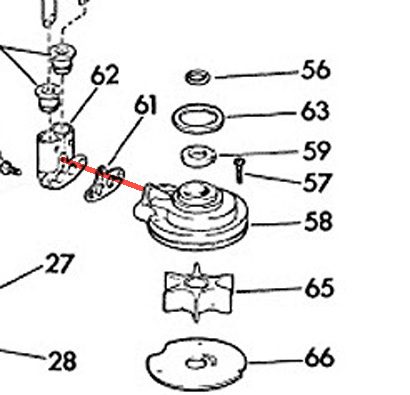

OK, so back to trying to look at that gearcase. You mentioned the water pump is in place, you may have to remove the impeller housing again in order to have a closer look at the water passage from the intake up to the pump. I’m hoping you did not use any sealer between the aluminum impeller housing and the SS plate anyway, you can probably leave the SS plate in place, which is what you sealed up. Post a few pictures of the inside of the impeller housing, perhaps we can see something there. Post a picture of the top of the SS plate as well.

But again, it is very important to consider what Bill is saying, these engines do not like to cool properly when run in a test tank…..

It sounds like you are trying to use some alternate gearcase in an effort to test, this doesn’t sound like a good idea….Like everyone has said, although the internals are very similar, the bolt patterns are different, and the water pump is different as well. Let’s skip this for now, an expensive and time consuming project, that may just create more confusion than good answers…-

This reply was modified 2 years, 8 months ago by

fleetwin. Reason: correction

August 1, 2021 at 6:35 pm #244076This is all great stuff, I am learning a lot here.

Yes, I am abandoning the idea of the other gearcase. It was just an idea, and not a great one.Bill,

This boat has not been on a boat in a lake since it was taken apart 10 or so year ago (time flies, it may have been sitting for even longer). My father has no recollection of an overheat issue.

I have been assuming that something was either clogged, corroded, or cracked from mice, salt, or ice in that time. My (limited) experience is with the 56,57 big twins and RDs that have the single water tube, no thermostat, and spit lots of water, even in a barrel.

I started down this pump rabbit hole through an abundance of caution about overheating and wrecking a motor.I will try to get this motor on a boat for a better test, pending some gearcase work, see below. The boat it is supposed to be on is not presently seaworthy so I need another boat option for the long shaft.

Other than excessive spray and hanging down so deep, is there any danger in running it on my other boat with a 15″ transom? 15′ aluminum, rated up to 60HP.At what temperature should the sensor(switch) on the head close? I can wire it up to a battery and light or just watch it with my multimeter. I will also keep an IR thermometer on it to confirm that it closes when it is hot enough.

Pictures of the impeller housing and SS plate attached.

Fleetwin,

I did your suggested leak down test. I knew the gearcase was leaking. It had water in it when I got into this motor, water that had been sitting for at least 10 years so I have assumed the bearings are trashed. I had refilled it with some gear oil that I had on hand for my tank testing of the motor, planning to deal with the gearcase later.

I did not know how bad it was leaking. With the water tubes installed, water runs down by the driveshaft seal and comes back up around the shift rod. That is maybe 13″ of head. It is not a stream, but a steady drip. Whether or not enough exhaust would take the opposite path and cause the pump to stop pushing water I dont know.Maybe I need to change gears for a while and start getting some heat/penetrating oil on the skeg screws so I can change out the shifter o-ring. It seems a little silly to put seals into this gearcase but the $25 seal kit might be the most practical thing at this point.

August 1, 2021 at 9:20 pm #244081August 1, 2021 at 11:31 pm #244098Frank,

Yes, I checked it. When I first went to change the impeller it was clogged but I cleared it. I Checked it again when I swapped back to the old impeller and it was still clear.August 1, 2021 at 11:35 pm #244099Is this bleed hole open?

Thanks for the picture Frank, worth much more than my blubbering…

OK, well the impeller housing and SS plate do look serviceable.

I fear I have confused this issue a bit…When I talk about a leak, I am not referring to water getting inside the gearcase diluting the gearcase lube. I am referring to a crack/porosity in the water passage that goes from the side plate up to and under the SS impeller plate…A leak in this area could cause air/exhaust to be sucked in under the pump. -

This reply was modified 2 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.