Home › Forum › Ask A Member › How to : Evinrude Speeditwin ..

- This topic has 43 replies, 13 voices, and was last updated 4 years, 9 months ago by

David Bartlett.

David Bartlett.

-

AuthorPosts

-

June 18, 2019 at 6:52 pm #177490

Ok pardon my ignorance, to make sure the ports are closed off the piston should be fully towards the plugs ? Ports are on the sides of the piston ?

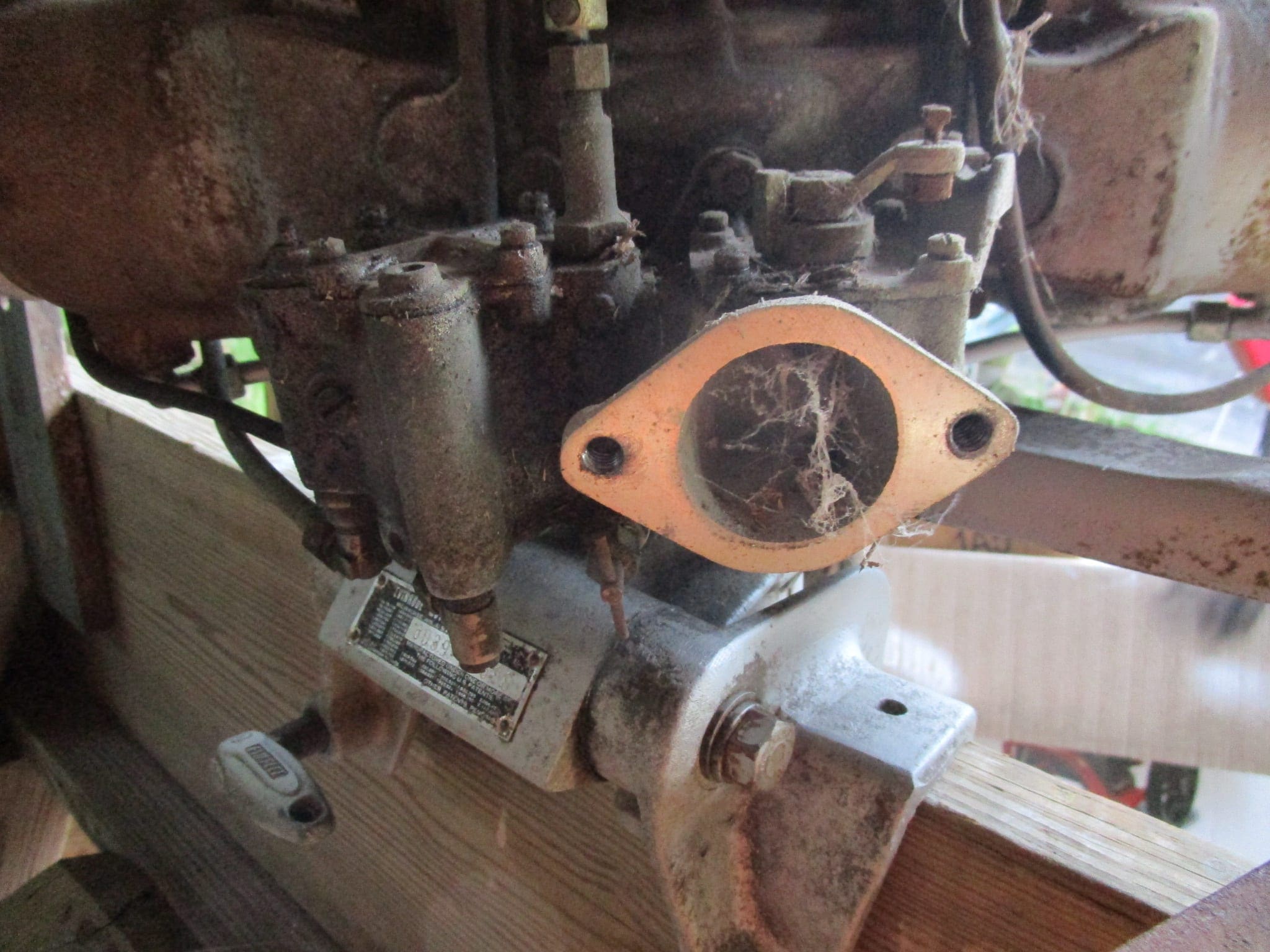

Also to grease the lower unit I assume that I remove the gear housing cap screw and fill with gear lube ? There is also a grease plug on the bottom of the foot that shows up on the diagram . Should I loosen that screw to make sure I’m getting lube all the way through the assembly ? The procedure would be greatly appreciated….June 18, 2019 at 8:45 pm #177506Well I thought everything was there . Looks like it’s missing the primer piston doodad … I couldn’t find the spider web on the parts list .. Lol !

I took the tank off turned it upside down and somehow poured smelly fuel on my boots .. I had thoughts of saving it to touch up the varnish on the boat !

What’s the best way to clean the tank out ? Anything I can pour in there to clean it ?June 19, 2019 at 6:29 pm #177572After reading a bit here I saw that the lower unit should be greased and not lubed . Still not sure how to grease it .

One of the suggested grease brands was cotton picker spindle grease from tractor supply https://www.tractorsupply.com/tsc/product/super-s-cotton-picker-spindle-grease-00?solr=1&cm_vc=-10005

Is this ok to use ?June 19, 2019 at 7:05 pm #177574After reading a bit here I saw that the lower unit should be greased and not lubed . Still not sure how to grease it .

One of the suggested grease brands was cotton picker spindle grease from tractor supply https://www.tractorsupply.com/tsc/product/super-s-cotton-picker-spindle-grease-00?solr=1&cm_vc=-10005

Is this ok to use ?

Yes. In Garry’s diagram you can see the grease fill plug. I think there is a vent plug somewhere to tell you when it is full, but has been a while since I had one of these motors.

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

-

This reply was modified 4 years, 10 months ago by

David Bartlett.

David Bartlett.

June 19, 2019 at 9:00 pm #177594Thanks David

Yeah I found the plug and the vent plug took them both out then squirted the grease from bottom till the old grease ran completely out of the vent then replaced the plugs .

I also did the 50/50 mix in the cylinders and got my son and sil to flip it over .. Not sure how long to leave it I shook it around a bit and Flipped it back after about 10 mins .

The tank I had some small chains so put them in with a qt of acetone and started shaking . Gunna leave acetone in over night and see what it looks like tomorrow..

I’m missing the primer piston. I took a nail and poked it into the housing . It did have spring so I assume it’s working properly. Any clue where to find a replacement?

Or just use a nail …LOL !

I will pick up some carb cleaner tomorrow.. Should I take the carb off to clean ?

Also how do I remove the flywheel?

Sorry about all the ?? I just have a ton of stuff running around in my head ..🙃June 20, 2019 at 8:34 pm #177683The tank is much cleaner but still a few spots need some work . Ran out of acetone so I put some Naphtha in that I had ..

sprayed the carb down with some cleaner.. I took the carb off without tearing up the gasket.. I guess I should take it apart to clean now ..

I’ve never torn a carb apart before so a bit nervous.. Is there anything I should avoid doing?June 21, 2019 at 5:18 pm #177720Sam,

Take your time & you have a wonderful motor in great shape. If your motor….of any kind never turn upside down unless you know the gearcase is completely dry. The reason is water will run into the pistons & cause rusting. I’m NOT saying the advice given is wrong as it has sat for a long time!!

Randy in Tampa & Garry are both very knowledgable with this great motor. Take pictures as you take the carb apart & check all fuel passages to be clear. Also study the functions to understand how the fuel is delivered when running. Please don’t put any rubber or plastic parts in carb cleaner as they will melt. Compression, clean fuel system & hot spark will give results.

Welcome to the club too!!June 21, 2019 at 8:31 pm #177732Thanks Jeff for the words of encouragement !

Unless you can get water in the crankcase by washing the outside of the motor with the water hose it probably was dry .. After looking the carb over and studying the diagram there is not really a whole lot to the carb . But then again I could tear up an anvil …To what extent should I tear it down . I took the float bowl cover off . Should I take the float assembly out or just spray everything out good . The same with the needle valve assembly .. There are 2 clean out screws on the bottom of that assembly .. Should I just take those out and spray cleaner in them ..

I just don’t want to screw something up inadvertently..

One thing I noticed was when I took the float cover off there was what looked like a disintegrated cork gasket all gummed up . Looks like the gaskets are fairly new …

I’ll take some pics tomorrow so maybe y’all could give it an assessment….

I know it may be a bit early but what about the water pump assembly . Is there anything I can do to clean it out to make sure there are no obstructions …

And I guess it should be run in a tub of water when the time comes . I have a nice big tub on wheels that I can use …-

This reply was modified 4 years, 10 months ago by

Samuel Phelps.

June 21, 2019 at 9:40 pm #177736Ok so lm not short on questions..

How do I take the flywheel off ?

And has anyone seen my compression tester ? 🤔June 22, 2019 at 1:28 pm #177761The flywheel has 3 threaded holes on top. Get a harmonic balancer puller or better yet, the OMC flywheel puller.

Google will give you some pictures and information on how to use it.

Do not beat on the crankshaft!!!

When you put things back together be sure to clean the tapers and do NOT lubricate. Tighten securely.

Someone will have the torque specs for this.

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

-

This reply was modified 4 years, 10 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.