Home › Forum › Ask A Member › Johnson CD-14 Frozen Pinion Gear-Shock Absorber

- This topic has 44 replies, 11 voices, and was last updated 6 years ago by

Don.

-

AuthorPosts

-

January 22, 2020 at 8:46 pm #192837

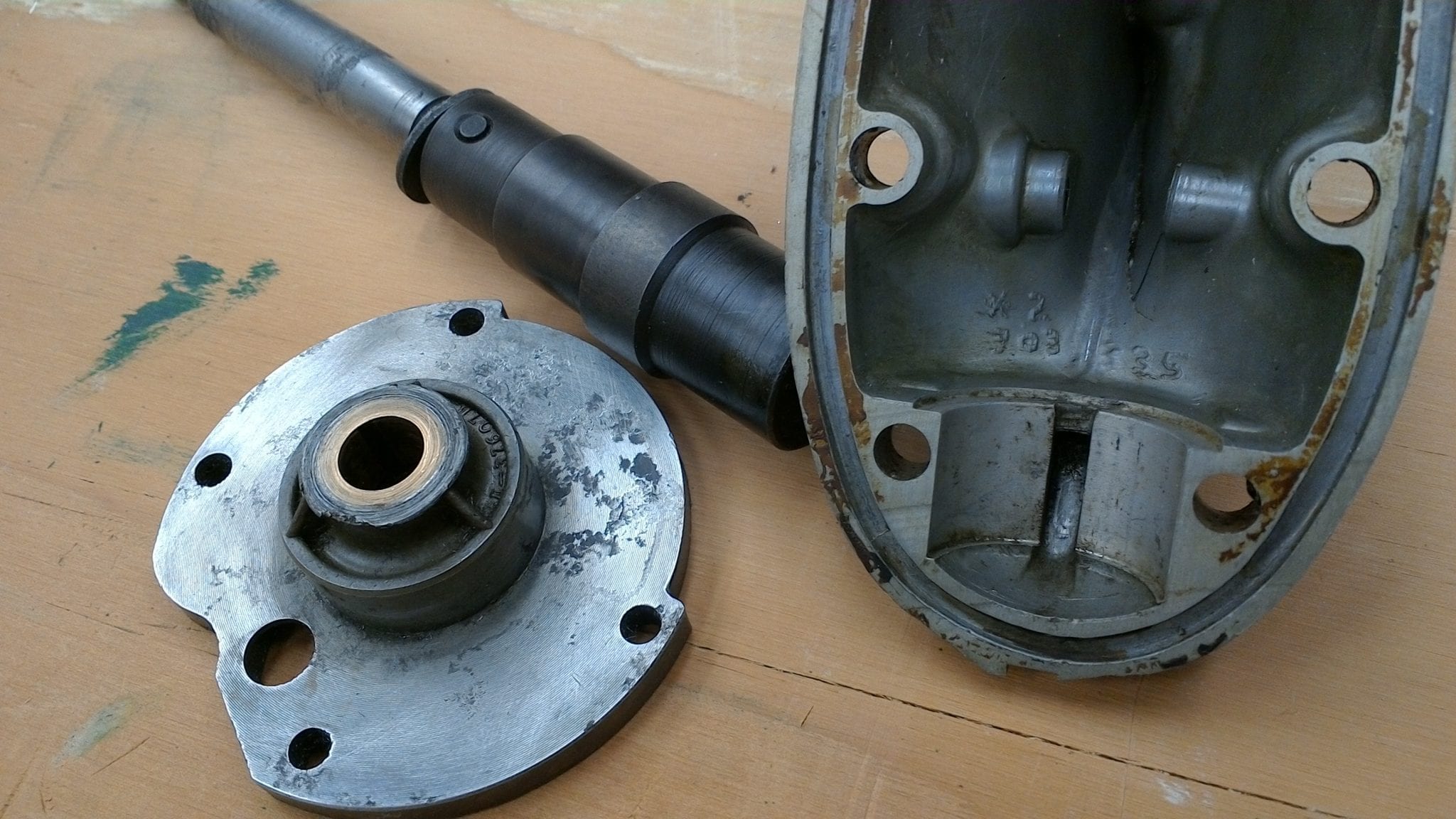

Thanks Don. I’m in Wilton,Ct. I have a welder i can call. Shock absorber doesn’t budge. i dont have a press so I need to get a member to look at it or replace it. See pics. How do it get the Yankee chapter event schedule?

-

This reply was modified 6 years, 1 month ago by

Mumbles.

Mumbles.

January 23, 2020 at 12:33 pm #192872If you’re going to beat it down to size, make sure you use at least a 2lb hammer as they do take some effort to move. Another way is to squeeze it in a vice if a press isn’t handy.

If welding or brazing the shock together, care has to be taken to keep the two pieces aligned while doing the job. The driveshaft fits into a pocket inside the bottom half and if it can’t drop into this pocket, the driveshaft will be a bit proud and you may have trouble replacing the powerhead.

January 24, 2020 at 11:18 am #192964OK, well your welder buddy can clean up that freeze crack. The driveshaft/bushing show little damage, if any, from rubbing, so no problem there. I’m sure you can find a machine shop that will press that driveshaft back down to the original height for little cost. Just be sure to have a look inside afterwards to make sure the shock spring isn’t actually broken….

Before you go too far with this project, I’m hoping you have evaluated the rest of the engine…Compression, ignition, fuel system. You surely don’t want to get the thing back together only to discover the engine has pitched a connecting rod or has low compression in one or both cylinders….

I will ask Gary if the 2020 meet schedule is out yet… There will be an on water meet later in the spring in the Hartford area, and the major on water meet will be held in Shelton in early September…DonJanuary 24, 2020 at 8:46 pm #193001Thanks Don,

I put it on the basement floor and held it with pliers and smashed it several times with a mallet and it squashed 👍. But to inspect the spring how do I get it apart? Twist or? And what does the pin on the side do?

Rest of engine I think is fine. It last ran 3 years ago. Started well.

Gary got back to me. Added me to the mailing list. The swap in Rocky Hill is next for me. Hope to have it running by then. Need to order gaskets etc now and call welder.

Thanks

JimFebruary 17, 2020 at 9:26 pm #195243Ok, crack in skeg is welded. He did a beautiful job. All gaskets and O-rings have arrived. Also got 3M 847 Gasket Sealing Compound, Triple Guard Grease and Loctite. I saw in a really great new YouTube video by Ben Ditmar, he recommends using BRP Gasket Sealing Compound. How does that differ from the 3M 847? Should I get that too? Hopefully get this thing back together next weekend.

Thanks,Jim

February 18, 2020 at 8:24 am #195266Gasket Sealiing Compound and 847 are entirely different products. 847 dries very quickly and sticky glue-like. Gasket compound dries only slightly and slowly and stays soft. Words chosen from my limited vocabulary.

-

This reply was modified 6 years ago by

frankr.

frankr.

February 18, 2020 at 11:28 am #1952793M 847 is used to seal metal to metal joints (often with spaghetti seal).. manuals call it “Type M” or “sealer 1000”

OMC (BRP) 508235 Gasket sealing compound comes in a can with a brush — I’ve used Permatex “High-Tack” but FrankR says the OMC stuff is much easier to clean up after. Mercury has a “Perfect Seal” compound.

http://www.omc-boats.org

http://www.aerocraft-boats.orgFebruary 18, 2020 at 11:45 am #195281Gasket Sealiing Compound and 847 are entirely different products. 847 dries very quickly and sticky glue-like. Gasket compound dries only slightly and slowly and stays soft. Words chosen from my limited vocabulary.

-

This reply was modified 6 years ago by

frankr.

frankr.

I like your dictionary.. The 847 dries quickly, is tough to use, and is much stronger than the gasket sealer. The best use for the 847 is when gluing the spaghetti seal in place on the skeg. The spaghetti seal would just pop right back out of the grooves if you tried to use the gasket sealer. This is a very critical step indeed. Once glued in place, the spaghetti seal must be properly trimmed so it butts up against the prop shaft bushing and seals properly. Frank has posted pictures of this procedure in previous posts. The gasket sealer can be used under the skeg screw heads, on the upper bushing gasket, and the shift linkage pivot screw gasket.

OK, so you have compressed the lower driveshaft, did you measure it? You are correct, there is no easy way to peak inside at that shock spring, and there is no way to take the driveshaft apart. Measure the lower driveshaft length and post your results. You could “dry fit” the lower driveshaft and upper bushing housing together prior to actual assembly, then check for some end lower driveshaft end play. If there is no end play, or the lower driveshaft binds when “dry fitted” together, it is still too long and probably needs to be replaced….

To “dry fit” these items:

Install the lower driveshaft into the upper gear housing. Then install the upper bushing, SS plate, and impeller housing, then snug up the three water pump screws. You don’t need to install the gasket for this test. Then install the key and pinion gear while the upper gear housing is inverted. Spin the pinion gear buy hand, it should spin freely, no binding on the upper housing. Now remove the pinion and key, then flip the gear housing right side up quickly, you should be able to hear a slight clunk as the lower driveshaft drops down slightly, indicated there is some end play…February 18, 2020 at 9:31 pm #195311Thanks Frankr and Phil. shock absorber is 6 11/16″ so I think I’m good. I’ll follow your dry fit instructions. Also,the pressure tester suggested in a previous reply to my thread is not available in my area, per Amazon. Strange. Does anyone have another brand/model? Maybe I’ll just go to Napa or AutoZone and see what they have.

JimFebruary 19, 2020 at 4:47 pm #195416unit turned out to be a real dud … after 5 minutes the handle was jamming half way and I ended up with total loss of pressure and vacum capabilities

Purchased dec19 2019 I was out of warranty return time when I tested my ETEC 75HP gearcase last week 🙁

Currently swapping mails with the supplier via AMAZON but I am not getting a good feeling on my $49 purchase If I end up high and dry with the supplier I will open it up (2 screws) and check out what is going on inside causing loss of pressure and.. vacum

Grandpa always said… ” buy the best tools you can afford ” 🙁

Joining AOMCI has priviledges 🙂

-

This reply was modified 6 years ago by

JACQUES.

-

This reply was modified 6 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.