Home › Forum › Ask A Member › Johnson TD20 / TN26 etc. – T-shooting Part 2

- This topic has 24 replies, 6 voices, and was last updated 10 years, 2 months ago by

garry-in-michigan.

garry-in-michigan.

-

AuthorPosts

-

April 26, 2015 at 5:15 pm #1332

Still can’t get my junk-box TD20 straightened out, so time to pursue new lines of thought..

From my previous work, I have clearly established that this motor has a bad misfire in at least one cylinder. It will only make reasonable power at high (near full) throttle settings, and things get progressively worse as the throttle is closed. By the point it’s reduced to half-throttle, it’s like one cyl. is completely cutting out – it runs very rough, shakes a lot and lowering it any further will stall it. Something is fundamentally wrong, here.

First off, on a TD20, there are two 1/8" holes drilled into the starboard side of the brass downtube, just below where the large circular clip rests in its groove. What is the purpose of these holes? Is it possible that water might exit from these holes – and if so, what would that indicate?

Secondly, there seems to be water running down the outside of the downtube.. it may be (partially) coming through these holes, but there’s also more water issuing from someplace higher up on the engine. I can’t quite tell where it’s escaping, but it’s somewhere in the region where the downtube meets the top of the transom bracket. There’s a bakelite bushing / washer there, you likely know the area I’m referring to..

It’s not the stream from the tell-tale port, which btw seems pretty good – very comparable to my ‘good’ TD20. So despite the noticeable amount of water that +is+ leaking out (of somewhere it’s not supposed to) it doesn’t seem to be starving the motor for cooling flow.

April 27, 2015 at 12:20 am #14832Since we haven’t had any replies, I’ll tack-on one more quickie..

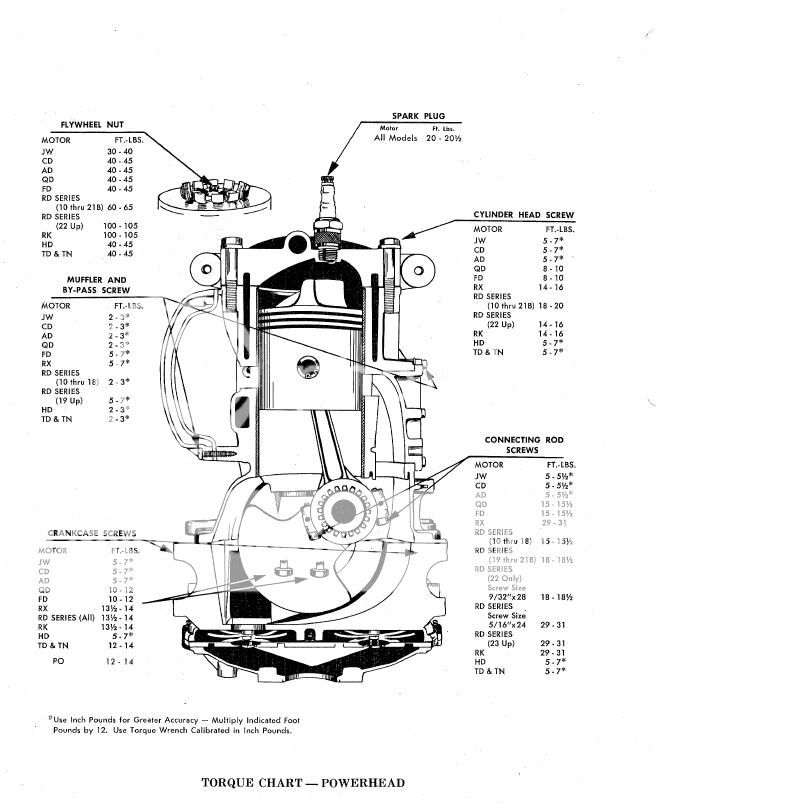

What is the correct head bolt torque for the TD20? The SM is silent on the matter, but I was able to infer 8-10 ft/lbs based on another model.

Seems a little bit light, but it may be OK?

April 27, 2015 at 2:28 am #148395 to 7 foot pounds for the cylinder head screws

April 27, 2015 at 4:27 am #14843quote Wedgie:5 to 7 foot pounds for the cylinder head screwsWow, even lower than I’d picked up. Thanks for the data – can you link me to a document that calls out this 5-7 ft/lb value?

April 27, 2015 at 12:10 pm #14848The two small holes in the midsection, just below the swivel bushing are factory vents. If all is right with your cooling system and waterpump, a fine spray will come out of these holes when the motor is running. Sometimes it is tough to see, but easier to see the results of the spray on the side of your test tank, or even put your hand in front of them.

I would be concerned if water was not spraying from these vents, but that is another discussion.

If water is coming out from under the powerhead, but the water is not from the vents or the telltale, then I don’t know. Maybe there is a base gasket problem, or one of the the external water tube connections is leaking.

Improvise-Adapt-Overcome

April 28, 2015 at 1:04 am #14904quote legendre:quote Wedgie:5 to 7 foot pounds for the cylinder head screwsWow, even lower than I’d picked up. Thanks for the data – can you link me to a document that calls out this 5-7 ft/lb value?

Here it is. I think Mumbles posted this on the old blue boards before the crash. luckily I printed it out and hung it on the wall. 🙂April 28, 2015 at 1:41 am #14906Here it is again.

April 28, 2015 at 9:51 pm #14950

April 28, 2015 at 9:51 pm #14950Why thank you very much, guys! Much appreciated.

So here’s the update: I put in the new head gasket, and it had essentially no effect. There’s still something very fundamentally wrong with this engine, and it’s at the short-block level. Starting to seriously consider things like crankcase leakage, particularly between the bottom & top end (primary compression leakage).

Crazy enough, the dang thing still starts on the first pull, practically every time!

But there’s still this issue of water running down the downtube, and apparently sputtering out of the two vent holes in the same tube. I mean if there’s a base gasket leak, sure, it might leak water externally – but could it be leaking enough water into the exhaust port to cause this issue? Do these motors still run OK with a bad base gasket?

April 28, 2015 at 10:00 pm #14952Wait a sec..

If the base gasket were bad (internally) could it cause water intended for the cooling loop to be pumped into the exhaust manifold, where it then enters the lower cylinder, causing all kinds of crappy running?

Because it really does start up great when cold, but then goes way downhill in about 5-10 seconds.. and the longer it runs, the worse it runs.

I’d appreciate any thoughts.. but I’m probably going to pull it apart anyway – as I’m at a total dead-end.

April 29, 2015 at 2:26 am #14975quote legendre:Wait a sec..If the base gasket were bad (internally) could it cause water intended for the cooling loop to be pumped into the exhaust manifold, where it then enters the lower cylinder, causing all kinds of crappy running?

Because it really does start up great when cold, but then goes way downhill in about 5-10 seconds.. and the longer it runs, the worse it runs.

I’d appreciate any thoughts.. but I’m probably going to pull it apart anyway – as I’m at a total dead-end.

You might be on to something here…as the impeller tube terminates at the base of the powerhead…could be flowing water in the exhaust, though would it not be pushed back out by compression/airflow?

What about a cracked block? I’d think a crack would get larger as the block heats up, would it not? -

AuthorPosts

- You must be logged in to reply to this topic.