Home › Forum › Ask A Member › Johnson TD20 / TN26 etc. – T-shooting Part 2

- This topic has 24 replies, 6 voices, and was last updated 10 years, 2 months ago by

garry-in-michigan.

garry-in-michigan.

-

AuthorPosts

-

May 3, 2015 at 7:29 pm #15267

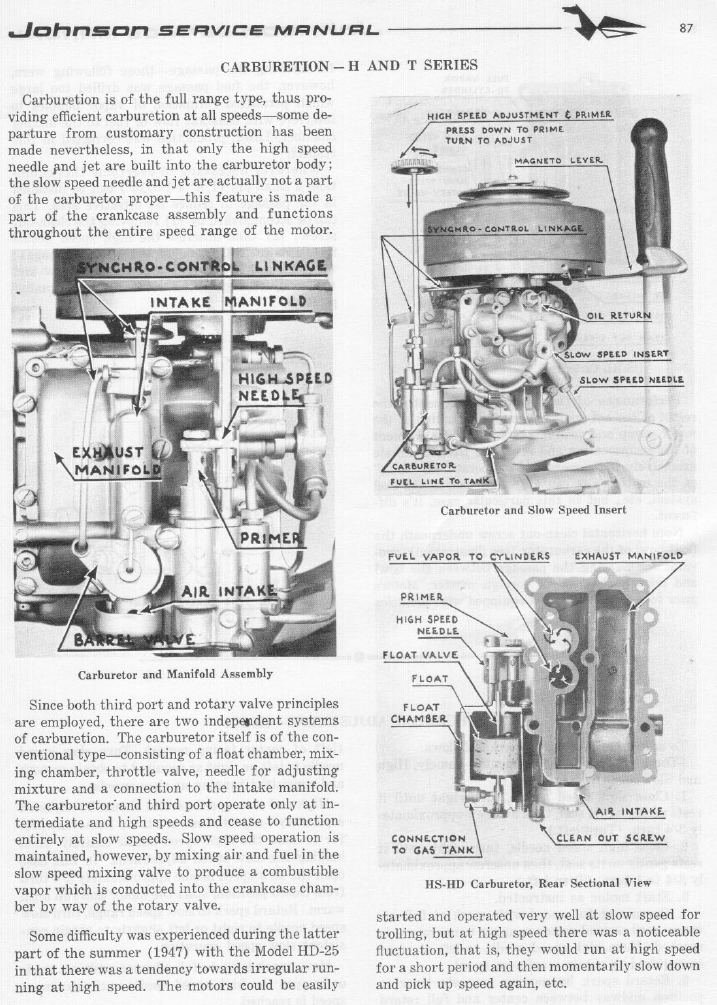

From the Factory manual …

May 3, 2015 at 8:13 pm #15271

May 3, 2015 at 8:13 pm #15271Quick question..

This motor has a small copper tube w/ fittings, that runs from the top of the low-speed carb body (on the case), then makes a 90′ bend and runs to a port in the bottom half of the case, near the top of the motor. This port passes though to the upper crank main bearing, where it communicates with a helical grove in the bronze bearing shell.

I’ve assumed the sole purpose of this system is to supply cool fuel / oil mixture to lubricate the upper main.. the vacuum produced in the case causing some of the mixture passing through the low-speed venturi to be drawn up through the tube and into the bearing.

Is this correct? Does the system serve any other function?

If the 90′ tube were blocked (or missing) what would be the result – aside from the obvious consequences of loss of lube to the bearing?

May 3, 2015 at 11:44 pm #15283That is a drain for oil that gets past the top main bearing. A slinger ring on the crankshaft throws the oil into a groove above the bearing that is channeled to that pickup tube. An early example of recycling. The center bearing is the slow speed rotary valve. The piston skirt acts as the valve for high speed operation by uncovering the third port behind the carburetor. Dammage or excessive ware to the piston skirt will efect the power output.

May 3, 2015 at 11:59 pm #15285

May 3, 2015 at 11:59 pm #15285Garry, my new best friend.. 😉

quote Garry in Tampa:That is a drain for oil that gets past the top main bearing. A slinger ring on the crankshaft throws the oil into a groove above the bearing that is channeled to that pickup tube. An early example of recycling. The center bearing is the slow speed rotary valve. The piston skirt acts as the valve for high speed operation by uncovering the third port behind the carburetor. Dammage or excessive ware to the piston skirt will efect the power output.

So you’re saying that the flow is opposite what I’d assumed? Excess oil leaves the crankcase and is.. returned to the crankcase to be burned.. via the slow-speed carb? Please forgive, but that doesn’t make much sense to me. If it’s already in the case to begin with, why isn’t that good enough? Why re-circulate it?

The middle main is lubed by the rotary valve hardware, the lower main by mist & gravity.. but gravity fights against lubing the upper. So where does the excess oil that would likewise pool at the lower main go – doesn’t that need to be removed as well?

Now depending on timing, the pressure in the case can be at, above or below atmospheric. If anything, I see more of a push-pull flow in that tube, rather than a unidirectional flow from inside to outside. Anyone else chime in on this?

May 4, 2015 at 2:38 pm #15320Since the low speed venturi is connected to the crankcase (Alternating between upper and lower) after the piston has closed the transfer port (AKA by-pass port) on it’s upward travel into compression, fuel and air are constantly drawn in. This includes the small amount from the channel at the Top Main bearing through the oil return line.

-

AuthorPosts

- You must be logged in to reply to this topic.