Home › Forum › Ask A Member › Kiss of death?

- This topic has 15 replies, 11 voices, and was last updated 3 years, 5 months ago by

fifty20ne.

fifty20ne.

-

AuthorPosts

-

November 23, 2020 at 11:30 pm #221437November 23, 2020 at 11:32 pm #221442

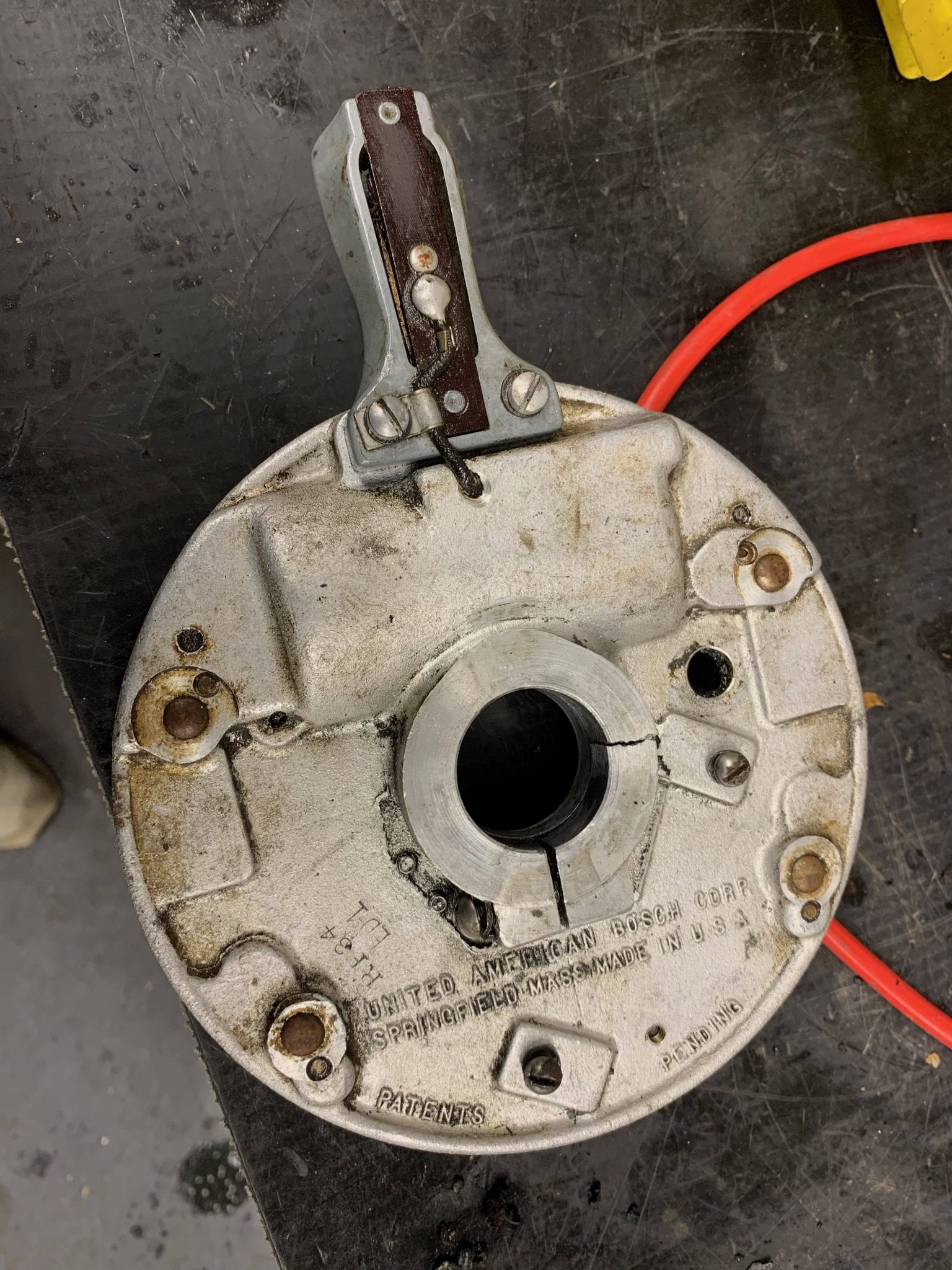

If there’s a will, there may be a way. Perhaps

the ring could be drilled and tapped and a

couple of #10 machine screws used to hold

the broken piece together?Prepare to be boarded!

November 23, 2020 at 11:45 pm #221447tried those aluminum welding rods ?? maybe STEEL WELD epoxy ???

a welding shop could be usefull shouldn’T be to hard to weld and polish it off

Joining AOMCI has priviledges 🙂

November 24, 2020 at 4:44 am #221461I would bolt the broken part using suitable packing, to line it up correctly,

then remove the broken part and V the break with a grinder, place it back correctly with the packing and have it aluminium welded and then remove the holding bolt plus the packing.You could then if you wanted to finish the job properly, remove the holding bolt and fill the hole with weld.

Monte NZ

November 24, 2020 at 5:46 am #221462It looks to me like that is a design that was just begging to break, anyway. I am not a welder but I would be surprised if welding it, even by a pro, would hold. Is this motor going to be a full restoration or just get ‘er goin’ and take a spin? If a full blown restoration, I would try to find a parts motor. If just running it for an hour or so, I would try using it just the way it is. It seems like it will still tighten enough to create enough friction to hold the plate from moving. I have a Mercury-built Thor single. It is no prize, when it is running. It sounds pretty unpleasant. If it were me, I would not sink a ton of time and money into that one you have. Just my opinion.

On another note, it says, “American Bosch, Springfield, MA.” Don’t Wico and Phelon also come from Springfield? It must have been the magneto capital of the world!

Long live American manufacturing!

November 24, 2020 at 8:05 am #221464Thanks for the input, everyone. All helpful and sound advice!

I agree with you, billw, that this motor is unlikely to be a good runner even if I get through a restoration. I won’t go deep into it. Funny thing is, the plate was very hard to move when it was on the motor. I thought I was doing the right thing taking it off to clean out the dried grease. Now I wish I could reapply it. Anyone have an extra tube of dried grease?

November 24, 2020 at 9:21 am #221469I have a Caille like that. The previous owner put a thin steel strap across the crack and bolted it down. It works really well. I have since found a good replacement mag plate, but I don’t run this particular motor so I didn’t bother changing it. Your mag could be welded and machined though it may break again. Aluminium brazing rods won’t work for this repair.

Wayne

Upper Canada Chapteruccaomci.com

November 24, 2020 at 9:22 am #221470 November 24, 2020 at 11:02 am #221473

November 24, 2020 at 11:02 am #221473Here is my two cents on this project. I would take the pinch bolt out and get a proper size hose clamp to go around the housing and use the clamp to tighten it up for some tension.

dale

get’em wet don’t let’em set!

November 24, 2020 at 11:55 am #221478More good suggestions, thanks!

-

AuthorPosts

- You must be logged in to reply to this topic.