Home › Forum › Ask A Member › Weak spark on 1973 20 Hp Johnson

- This topic has 72 replies, 13 voices, and was last updated 3 years, 5 months ago by

fleetwin.

-

AuthorPosts

-

August 10, 2020 at 1:53 am #211246

Regarding the flood: Maybe the core plug on the bottom of the cylinder head?

#15 (part number 202310) in the diagram at:

http://www.omc-boats.org

http://www.aerocraft-boats.orgAugust 10, 2020 at 7:47 am #211251I think Phil has found the leak culprit….

October 4, 2020 at 5:38 pm #217798Please get me the ideal why it starts missing a lot. I bought a good use cab and replace the old cab. The new cab had been cleaned.

https://youtu.be/vkUWYnyjWCYOctober 5, 2020 at 8:07 pm #217905OK, well audio quality can always fool me… I’m guessing the snapping I hear is the disconnected low speed needle linkage slapping against the lower pan… But, the engine is certainly coughing/spitting lean. It almost sounds like it is dropping a cylinder, but that might just be its reaction from the lean spit/cough, again audio quality can be deceiving.

Are you sure the carb butterfly is completely closed? If not, it will certainly react like this.

What was wrong with the original carburetor? What carburetor did you replace it with? Are there any obvious external crankcase leaks? You would probably see obvious spray when the engine coughs lean if there is an external leak.Usually the 20hps have a carburetor with a smaller throat, sometimes the intake manifold is restricted also. Putting a carb with a larger throat on this engine might cause a fuel/air flow issue through a intake manifold with a smaller opening for the carburetor…

-

This reply was modified 3 years, 6 months ago by

fleetwin.

October 6, 2020 at 4:57 pm #217964The engine was coughing/spitting very obviously. Since I put in the new used carb (bought from E-bay for $40 since it looks very good Johnson OMC Evinrude Carburetor for 1973 20 Hp 385814 Removed from a freshwater 1973 Johnson 20HP Model 20R73A). The used carb came from the same my model number. The old carb was in not good shape cosmetically. It was hard start with the old carb so I try to get a new used one to see if the condition improved. Attachment are the picture of the new used Carb. But after I took the video of the motor running. I stopped the motor and I could not ever start it again even though after many pulls and adjusted the idle needle. The Carb had been cleaned before installed on the motor.

-

This reply was modified 3 years, 6 months ago by

Evinrude 25.

October 6, 2020 at 7:25 pm #217973OK, so the carb is the exact replacement… From the looks of that powerhead, I’m guessing the carb was toast and you never tried running it with the original carb installed. So, there might be a problem with your replacement carb even though you gave it a basic check/cleaning…. You know what you might try…..Try the carb from your older 20hp on the newer engine, even though all the all the linkages might not hook up perfectly… Once again, are you sure the carb throttle valve is closing fully at idle? You can have a better look at its throttle plate once you remove the carb, perhaps the throttle shaft is binding or something like that. So, now you can’t even get the motor started, is that correct? One or both of the plugs might be fouled from all the sneezing, misfiring. Trying a different carb will give good information quickly. It is safe to “assssume” there is no big problem with your original carb if the engine runs the same way with the older carb installed…Again, please make sure the throttle plate is closing fully at idle…

October 6, 2020 at 9:03 pm #217990Hi Fleetwin,

Actually, there was 2 videos posted previously on August 8 and August 9, the motor ran with the original carb! The second video shown the water came out of the bottom of the head and I fixed it (a member of this forum pointed out that the head lost the plug). Later on, it was hard to start the motor so I had decided to purchase a used carb with better condition. As per your suggestion, I will swap the carb from my other 1966 20 hp to this motor and report to you later.October 7, 2020 at 12:20 am #218007Hey guys, i went back to beginning of this post back in August and reviewed all the on goings of this motor since August.

It seemed like you got the ignition resolved and carburetor issue somewhat resolved (you have not been able to dial it on boat or in a test tank for the final settings). I am referring back to post #211151.

August 8, 2020 at 2:32 pm

#211151

ReplySuccess. I got it run!

Now, you had the gear case off the motor and seemed to run decent. You then put the gear case back on the motor and started it up in the barrel and experienced a significant amount of water coming out of near the bottom of the cylinder head. Phil made a comment that it could be the cylinder head plug. It seemed that you resolve the leaking from the base of the cylinder head, but maybe not.

I have a suspicion, that water is leaking into the cylinders( most probably the lower cylinder) and causing it to run rough and erratic.

*****Looking back at your very first post of this thread, you made comment of the things that you had done and evaluated.*****

-

I have taken a part the power head and rehone the cylinder, both of them got 115/113 psi. The block has been sand blasted and paint back base color

. So far I got done step #1.

Step 2: Spark. It did not have spark so I have replaced two external ignition coils, new points and condensers. I got OK spark on the cylinder #2 and intermittent spark on cylinder #1 (sometime no spark at all). I have set the gap of 0.020″. The only thing I did not replace is the Charging Coil 581130 (Driver Coil). There is only one charge coil on OMC Armature Plate Assembly. Does it have 2 independent coil inside for each cylinder or only one for both? Does the point gap (0.020″) affect the spark quality?

Do I need to replace the Charging coil too?

All opinions and helps are welcomed.I have some specific questions that might clarify if you are having a water entering your cylinders.

– When you removed your cylinder head to hone the cylinders, did you replace the cylinder head gasket or did your reuse the old one?

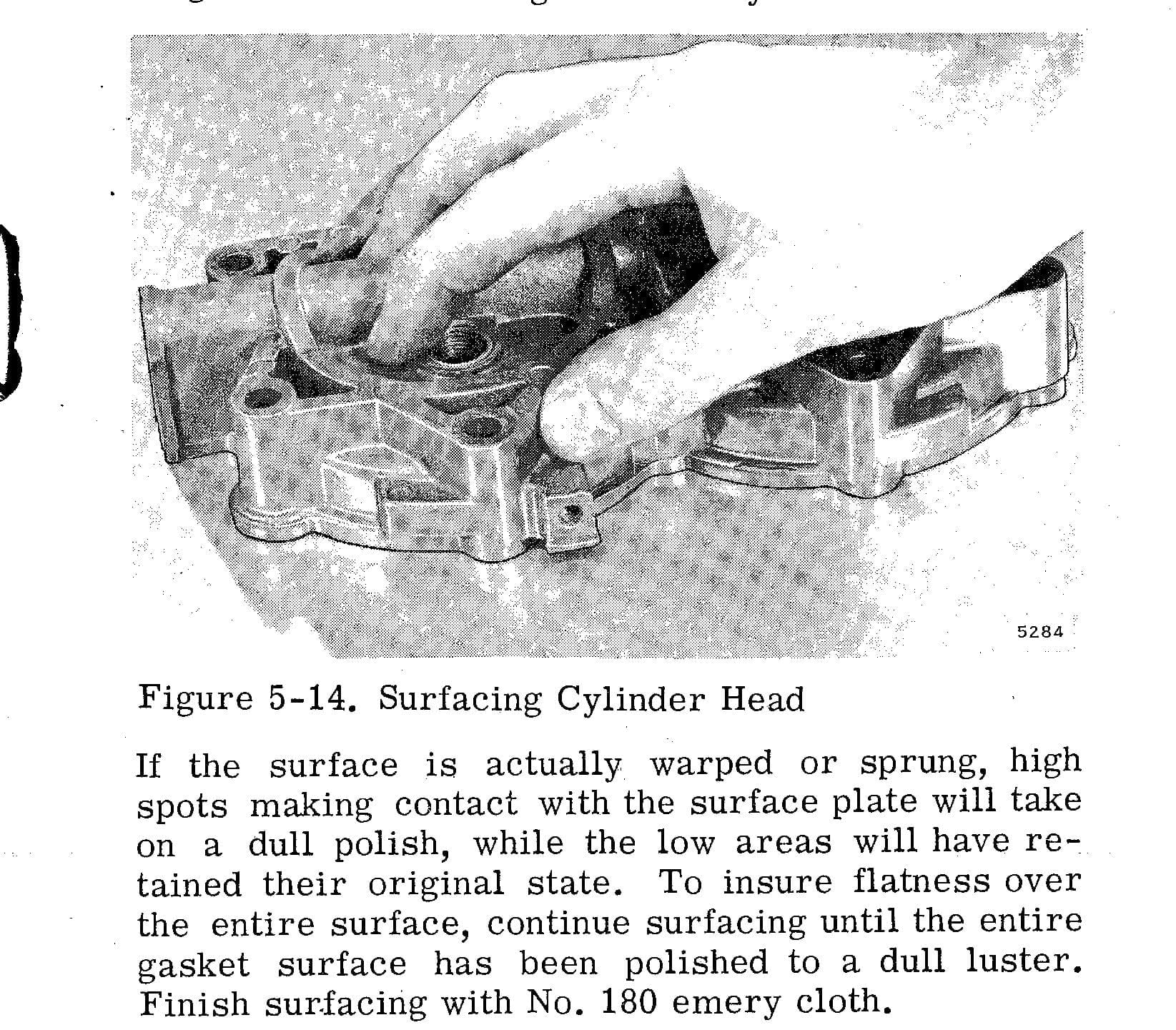

– Prior to putting the cylinder head back did you clean and true the mating surfaces with sandpaper in a figure 8 pattern?

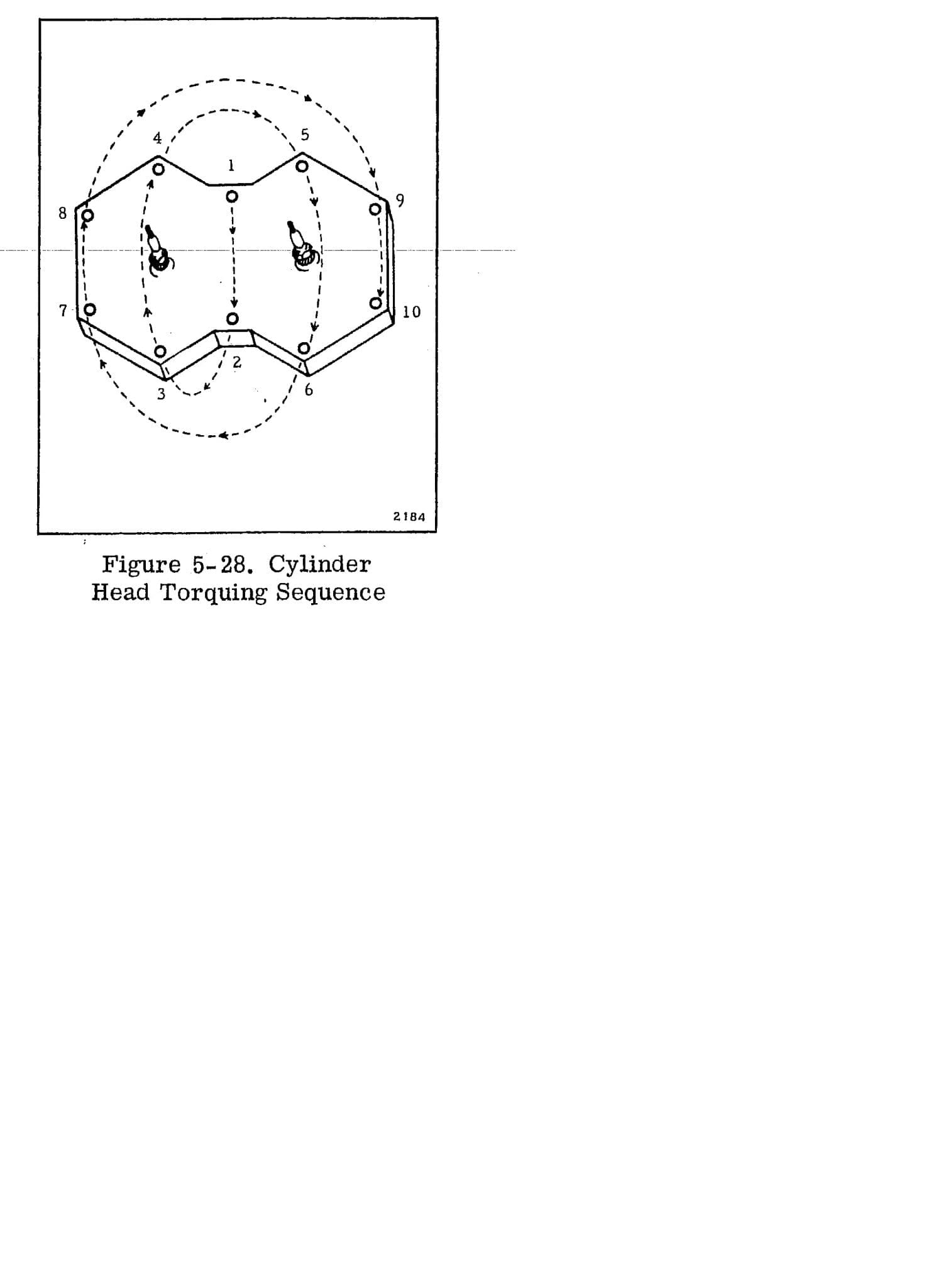

– Did you torque the cylinder head bolts 96 to 120

- inch pounds

(not foot pounds) in at least a 2 to 3 pass system. 1/4 torque the first pass, then about half torque the second pass and full torque the final pass. (it is advisable to do an additional full torque pass after the motor has come up to temp and run to compensate for heat expansion). There is a torque pattern that helps with even application of torque across the cylinder head surface. I will post a diagram below.

- – Please remove both spark plugs to look at there condition.

– Do the spark plugs have water droplets on them or look like they are clean from water exposure? They should be dry and slightly grayish from combustion.

If you reuse a old cylinder head gasket, do not clean and true the cylinder head mating surfaces or fail to torque the cylinder head you run the risk of water entering the cylinder from the cooling pathways.

Again, this is just speculation and may not be a factor if you did all the above things. I’ll butt out, I just wanted verify that there was not a water intrusion issue.

October 7, 2020 at 8:13 am #218016Just want to review, it has been a long thread…Did you actually pull this powerhead all apart, or did you just pull the head and clean up the cylinders with emery cloth?

October 9, 2020 at 7:49 am #218191Hello Fleetwin,

Here are the history of what I have done.

1) The ignition resolved with great learning about low tension ignition! Complete brand new all the ignition parts.

2) Ran OK with the original carb without the lower unit installed.

3) Ran in the barrel and found the water came out of the bottom cylinder head. Removed the cylinder head and installed the plug.

4) It was hard to start and tried to adjust the carb, Cleaned the carb again and it ran a couple times but when shut it off, it would not run!

5) Decided to buy a better condition carb and ran it as shown in the last video.Answer specific questions:

– When you removed your cylinder head to hone the cylinders, did you replace the cylinder head gasket or did your reuse the old one? The block completed torn apart and honed the cylinders, clean up carbon on the piston grooves. I reused the gasket!– Prior to putting the cylinder head back did you clean and true the mating surfaces with sandpaper in a figure 8 pattern? NO but I clean up the gasket, head and block surface with emery cloth.

– Did you torque the cylinder head bolts 96 to 120. I found the information form Iboat forum for the torque spec and I did but I forgot the number. The problem that I could not torque 2 bolt at the bottom of the cylinder since there was no room to get the torque gun there so I tried my best with the wrench! Otherwise I have to remove the block out. In your experience, is there any way to torque these bolt without remove the block? I did two pass, 6 ft.lb and then final torque value with the head torque sequence.

I attach the spark plug picture of the motor. The one on the left side is the bottom cylinder plug. I did not see the droplet on the spark plug.

-

This reply was modified 3 years, 6 months ago by

Evinrude 25.

-

This reply was modified 3 years, 6 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.