Home › Forum › Ask A Member › 1958 Johnson 35HP outboard starter went bye bye!

- This topic has 18 replies, 11 voices, and was last updated 7 years, 1 month ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

March 11, 2017 at 3:54 pm #54132

Sorry Chris, I forgot to answer your last question. If I put the battery directly onto the starter, it DOES NOT spin the starter as it should. If brushes are all it needs I would be thrilled. But How do you know if it is just the brushes that are bad?

March 11, 2017 at 3:58 pm #54133Sounds reasonable then.

You will need to open it up, clean and inspect.

If you are not comfortable with starters, any local starter/alternator repair shop will rebuild for much less than the cost of new.

March 11, 2017 at 11:12 pm #54153March 12, 2017 at 12:46 am #54161call discount starter and alternator I got my last one for about $70 including shipping call them up give the information on your starter and they’ll match it with a brand-new starter …. 🙂

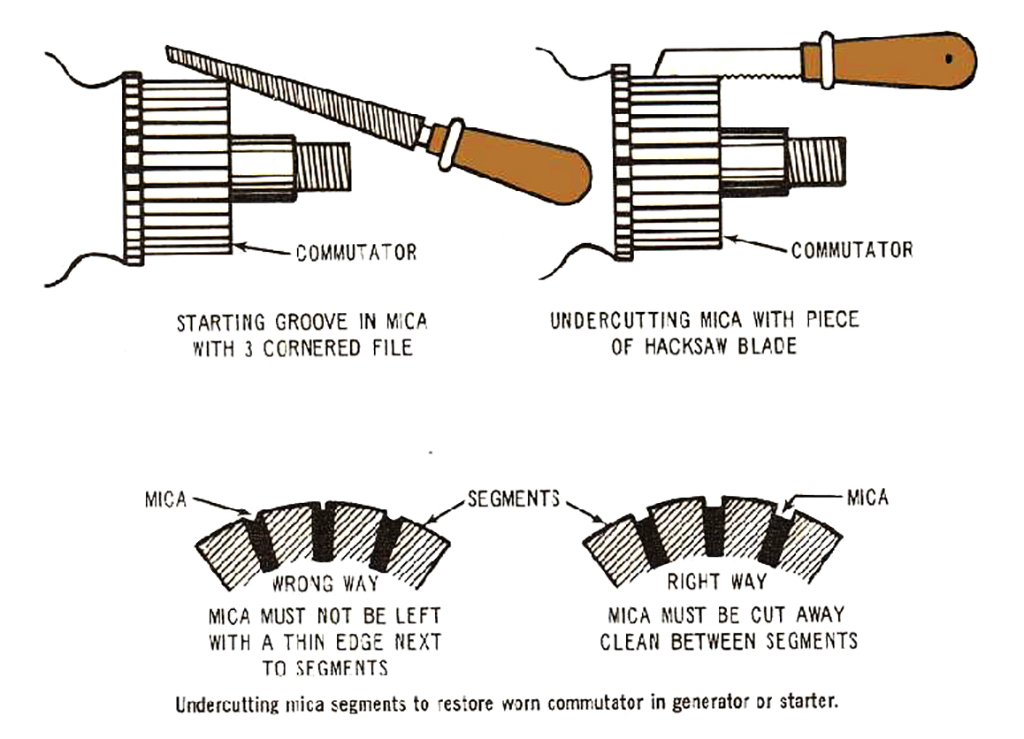

March 12, 2017 at 12:13 pm #54183Take a look at the commutator on the end of the armature, or where the brushes ride. You can chuck the whole assembly in a drill press, or, a cordless drill will do… spin the assembly slowly while using some fine emery cloth to clean up the commutator. It takes very little, so don’t take off to much. Then clean each groove carefully, between each window to remove dirt and contaminates. That may be all it needs. I’ve fixed many starters and even trolling motors this way. Most shops won’t take the time to do this, and would rather replace the starter to save time, and make a few bucks. http://dansmc.com/cut_commutator.jpg

March 12, 2017 at 9:18 pm #54201Thanks Jerry. I’m going to give this a try. Got nothing to lose right?

March 13, 2017 at 2:09 am #54221Position the piece of hacksaw blade so it cuts on the pull stroke. That makes it easier to control. I use 600 grit carborundum (wet-or-dry) paper to polish the commutator, then clean the mica separators. If there is a bad contact with the brush cables, current through the brush springs can overheat them and make them loose tension. Cranking with a weak battery or excessive cranking will over heat The starter, melting the solder holding the wires to the contacts. A stalled starter will draw 200 amps. If confronted with a weak battery, starting effort will be reduced 40% by pulling out the starter rope 6 or 8 inches to activate the compression release. The upper bearing tends to ware on one side, turning it 180 degrees on reassembly will extend his life. . . 😉

March 13, 2017 at 1:36 pm #54251

March 13, 2017 at 1:36 pm #54251Thanks Garry for the diagram !!

I just pulled my two 1970 Porter Cable belt sanders out of a 20 year

hibernation and both exhibit the same symptoms as the above mentioned

starter. The brushes are good so I will clean up the innards as you describe.March 14, 2017 at 12:04 am #54287I’m betting the brushes and commutator surfaces are OK and the problem lies with the commutator shorting out to the lower end plate. The weight of the armature wears out the thrust washer(s) allowing the ends of the commutator segments to make contact with the end plate. looking at your photo I can see the large circular area on the end plate probably caused by the segments dragging and the marks sure look to be the same diameter as the commutator. The way you describe the starter being sluggish to is also a sign of an internal short.

Did you find a thrust washer or two in there when you took it apart? If you clean up the plate and lay it over the end of the armature you’ll see how close together the parts are. In these cases I make new washers out of Acetal (Delrin) which is non conductive and also acts as a bearing surface.

-

AuthorPosts

- You must be logged in to reply to this topic.