Home › Forum › Ask A Member › Home made flywheels?

- This topic has 23 replies, 8 voices, and was last updated 5 years, 11 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

May 20, 2018 at 3:17 pm #76404May 20, 2018 at 5:50 pm #76418

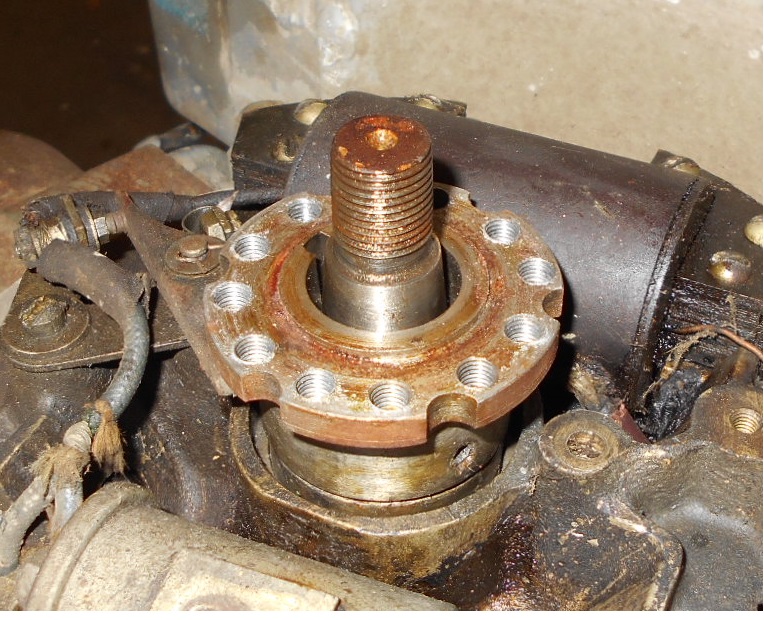

It doesn’t even give you the capability to switch flywheel orientation and still use all 12 bolts. I’d be surprised if the hole spacing is even equal all the way around the bolt circle. From what I can see, it doesn’t appear to be.

No, its not factory. Quit believing that it "might" be.

It’s an attempt at making a completely different brand of magneto work on an engine it was never meant to be installed on in the first place. That’s the beginning and the end of the story. Its not a prototype testing set up, it’s not a factory approved replacement for the original flywheel and timer, and it may not even have been successful at replacing the parts that were there originally.

Sorry if I’m shooting somebody’s theory in the foot, but that’s really all there is to it, pure and simple like.

Whether its a good or bad attempt is subject to opinion. If the original crankshaft taper isn’t effed up, consider yourself lucky. you might be able to get it running using this "modification", but I don’t recommend it.

Hope this helps.

Best,

PM T2May 20, 2018 at 6:36 pm #76419quote Tubs:The flange doesn’t have a taper.

It is made for a straight shaft.

That is as much of an issue as

the all the bolt holes. With the

factories machining capabilities

it unlikely they would do

anything like this.Tubs, it’s hard to see, but there’s actually two different tapers in that

hub. The lower one did fit the crank, and even

though the taper didn’t have as much bearing

as a normal flywheel, it took a lot of effort

with my puller before it "popped" off.Prepare to be boarded!

May 21, 2018 at 12:45 pm #76473I do like thinking outside the box and that’s’ all I was doing not saying it was factual information. 2 tapers that is interesting wonder what different engines those tapers would fit and I also do wonder if the flywheel can be moved in 12 separate positions using that hub as others just mentioned. I also wonder how old the guys were that actually did the testing in 1930 I would guesstimate in their 40’s and 50’s that would make them pretty old today lol so who really knows how they really tested timing except those guys. I would guess that information would be kept private.

Joe

May 21, 2018 at 1:00 pm #76475The trouble I find with suggestions like that is that somebody will latch onto some off-the-wall concept and then adopt the attitude "well how do you know they DIDN’T do it at the factory that way, can you prove it"?

Which is just effing stupid, because they know full effing well that its pretty much impossible to prove that something WASN’T done.

I believe the more logical approach is that if anybody has a "theory" they need to be able to back it up with factual evidence before broadcasting it.

The onus should not be on me to prove it didn’t happen; rather, the onus should be on THEM to prove that it did!

What we know from a factual point of view is that the parts in question are not Elto bits and don’t belong on that motor. Period. Somebody monkey-fabbed them up. They tried to make do with what they could put together.

To answer your question – the other motor that the taper would fit would likely be the motor that donated the flywheel in the first place. Theoretically, the flywheel could be put in 12 different orientations, but as I already said I’ll bet that the bolt holes will only line up in one or two positions at best, the spacing looks different and the bolt circle might not be perfectly round either, and even so, if you flip the flywheel 180 degrees, you really think you’ll still have spark delivered at the correct time in the firing sequence?

Over and out

PM T2

May 21, 2018 at 1:40 pm #76477My guess on the reason for mods is that parts broke. Those battery ignition Eltos have a few areas that do break if not properly maintained. My Senior Speedster had the connection rod that opens and closes the points broken off at the small end, it needs to be oiled manually once in a while, mine wasn’t I guess. My rudder twin had the timer box cracked in half, a common problem. also lack of lubrication. I’m sure the person who engineered this probably couldn’t get parts and did what he could to get it running again, many years ago.

May 21, 2018 at 1:42 pm #76478I do agree with you on the fact that will the flywheel line up in the 12 different positions that is a good question. If so then yes you could flip the flywheel different degrees along with moving the points cam to a different positions to get spark at different positions on different engines in the correct firing sequence. I would think 12 holes were used to give it the ability to be moved smaller degrees + or -.

PM T2 I do respect your knowledge of outboards. Have you ever seen a condenser that large used on outboards? If so which ones? It would look to me it has the ability to hold a lot of charge more so than just a normal condenser if the 12 bolt holes line up then that maybe why its so large.

Joe

May 21, 2018 at 4:11 pm #76488May 21, 2018 at 9:20 pm #76504Tubs, for now, I have a Speeditwin flywheel and magneto lined up,

so I’m hoping it works. I would like to put the Speedster back

to original some day though.

Who is reproducing the timers?

Thanks.Just found a good video by Peter Hunn on the Elto Speedsters.

https://youtu.be/4jCsE7vtvPkAnd another video about a 1928 Elto Speedster "Rat Motor" 😉

Prepare to be boarded!

May 22, 2018 at 3:09 pm #76563The large condenser used in this application does seem ridiculous. Having said that – I have seen some of the early P-series Johnson where they also used a very large diameter condenser when compared to what was on the A-series motors. Not sure that it was the same diameter as the coil – but it was big. I might have a dead one laying around somewhere…..

But with everything else on that set-up being as cobbled as it is, I guess using an overdosed condenser was just another part of the equation.

Hope this helps.

Best,

PM T2 -

AuthorPosts

- You must be logged in to reply to this topic.