Home › Forum › Ask A Member › Johnson HD-25 Low Speed Insert Lead Seat

- This topic has 12 replies, 5 voices, and was last updated 7 years, 1 month ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

March 22, 2017 at 11:08 pm #6591

On the HD-25 I’m working on, the Low Speed Insert / Nozzle

(that’s lightly pressed in the crankcase) must need a new

lead seat, as the insert is too far in and the needle body was hitting

on the crankcase, perhaps preventing a good seal on the nozzle.

The parts manual says it’s part 43-298.

The repair manual calls it a "lead seat" with "small ribs",

that should face "down".I’ve searched for lead washers, and see nothing that small.

(3/8" OD, 1/8" ID )Needless to say, I’ve search the original part number and get "no hits".

Any suggestions on what I could use for a lead seat?

Thanks.Prepare to be boarded!

March 23, 2017 at 12:12 am #54729Sent you a PM, Ed

March 23, 2017 at 1:06 am #54732Ed, I PM’d you back, but it’s sitting in my outbox.

Either your mailbox is full, or perhaps it sits in

my "outbox" until you read it?Prepare to be boarded!

March 23, 2017 at 5:24 am #54744If you find a NOS one, let me know what they look like as I’ve wondered before if they couldn’t be cut out of lead flashing material.

March 23, 2017 at 1:08 pm #54751I ordered a couple of NOS ones from

an AOMCI member 🙂

and I will post a photo with measurements upon arrival.

Good idea on the lead flashing material….. haven’t

seen any of that in the 100 years though… wonder

if it’s still used?Prepare to be boarded!

March 23, 2017 at 3:28 pm #54754In regards to lead flashing availability ,think i saw it at a roofing or plumbing supply company in Seattle last year. EDIT

"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonMarch 23, 2017 at 4:05 pm #54756Keep your eyes open for an older house getting a new roof put on. Usually the roofers will replace the lead flashing on the vent pipes with modern plasticky ones and trash the lead ones.

March 23, 2017 at 7:26 pm #54766Diecast holes in castings are made with a slight taper to be easier to take out of the mold. This taper is what holds the low speed intake venturi in place. It may be removed in the very rare case of a blockage unable to be cleared by unscrewing and polishing the low speed needle. Know that each time this is done, the hole wares a little bigger. My solution to one that was too lose was to roll the slow speed venturi insert between two pieces of course sand paper to toughen the surface and then coat it with high strength LockTight and install it to the proper depth. After a few days, I clean it thoroughly and install the fuel line and needle valve. If this fails a thin lead tube with a shoulder on one end is used to take up the space. I saw one that had oil around the insert. It rotated easily when I disconnected the fuel line. Some one had used a Helicoil in the crank case and had threaded the insert. It was imposable line up properly. It was in to far or out too far. I settled for out too far with a lot of sealer on the threads. Sure to cause problems for the next mechanic that doesn’t realize it has been threaded. . . 😀

March 24, 2017 at 12:32 pm #54802

March 24, 2017 at 12:32 pm #54802Garry, my low speed insert / nozzle pried out easy with two screw drivers.

I was thinking about using a little loc-tite upon installation.When I get the new lead seal, should I attempt to "dig" out

the old one, or just add the new on top of old?Looks like it might be a pain to dig out. I suppose one could

split the crankcase, but not sure one could "poke" at the

old seal from the inside of the front case?Is there a proper distance these nozzles should be installed at?

I see nothing in the manual about that.

Mine was "bottomed out".The inside of my nozzle hole appears a little "out of round",

like a used sand blast nozzle gets.

Will this affect the performance of the engine?

Thanks!Prepare to be boarded!

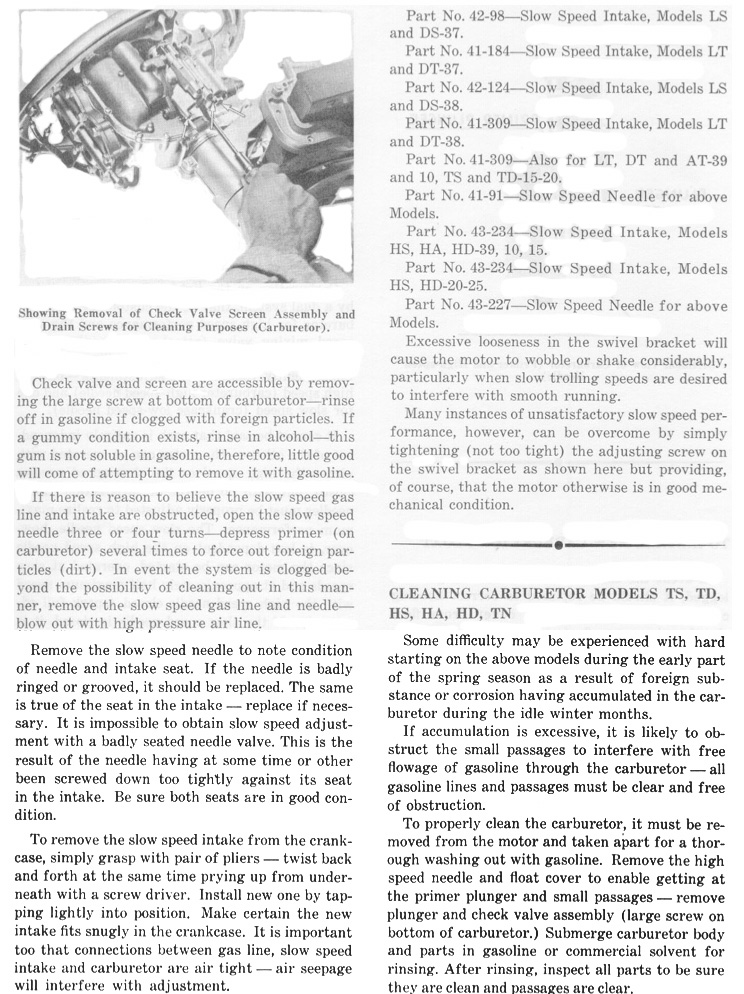

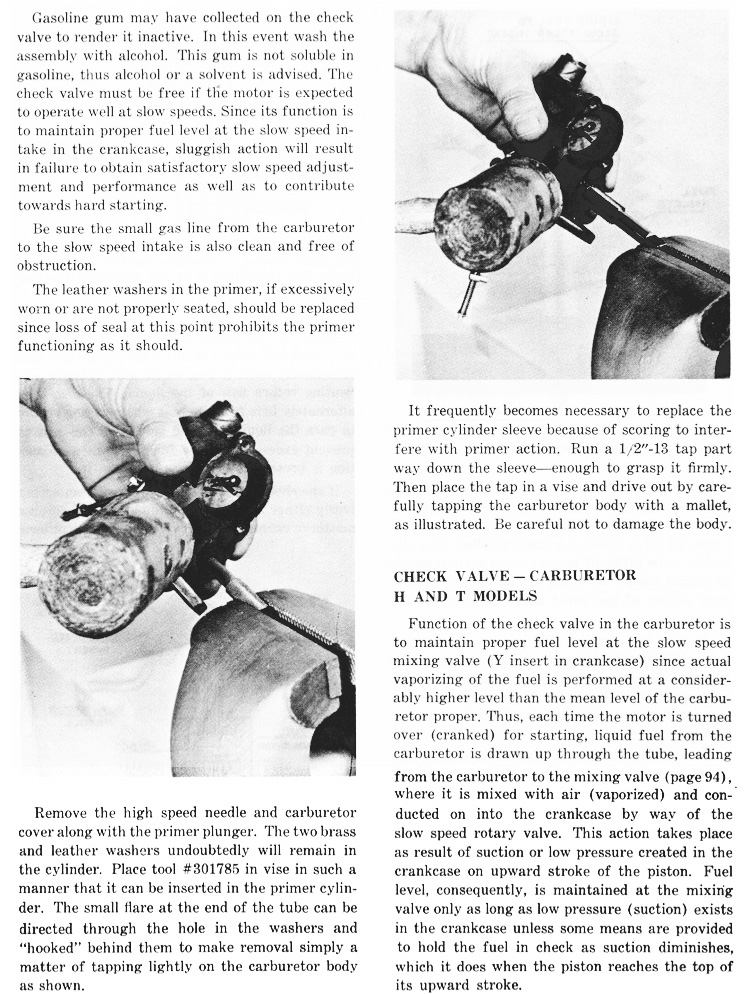

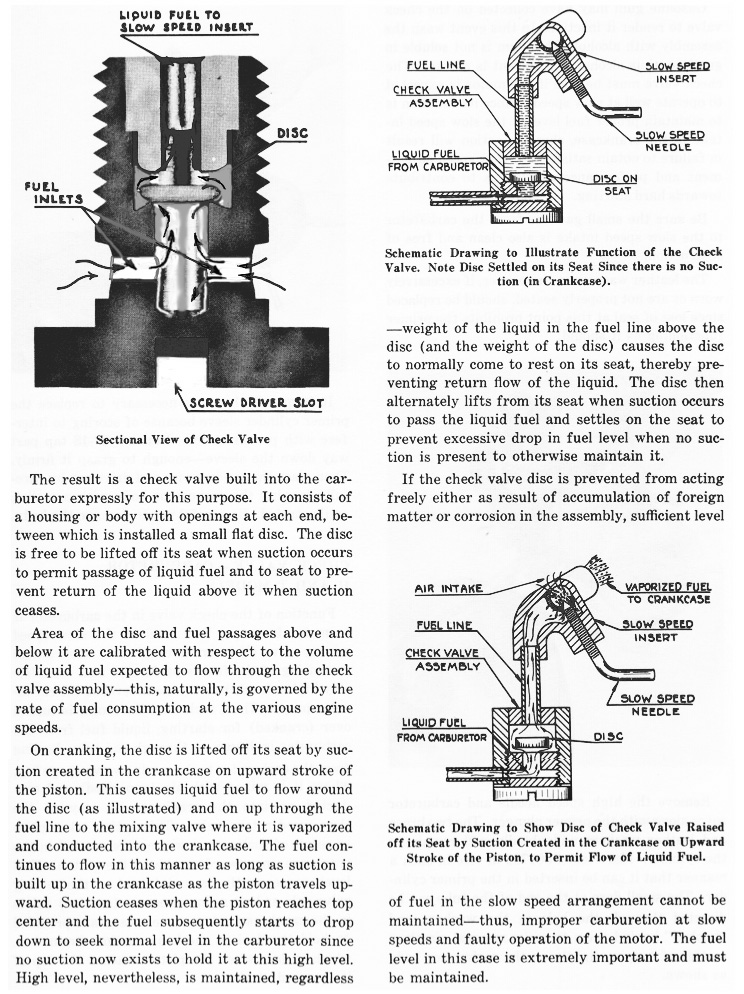

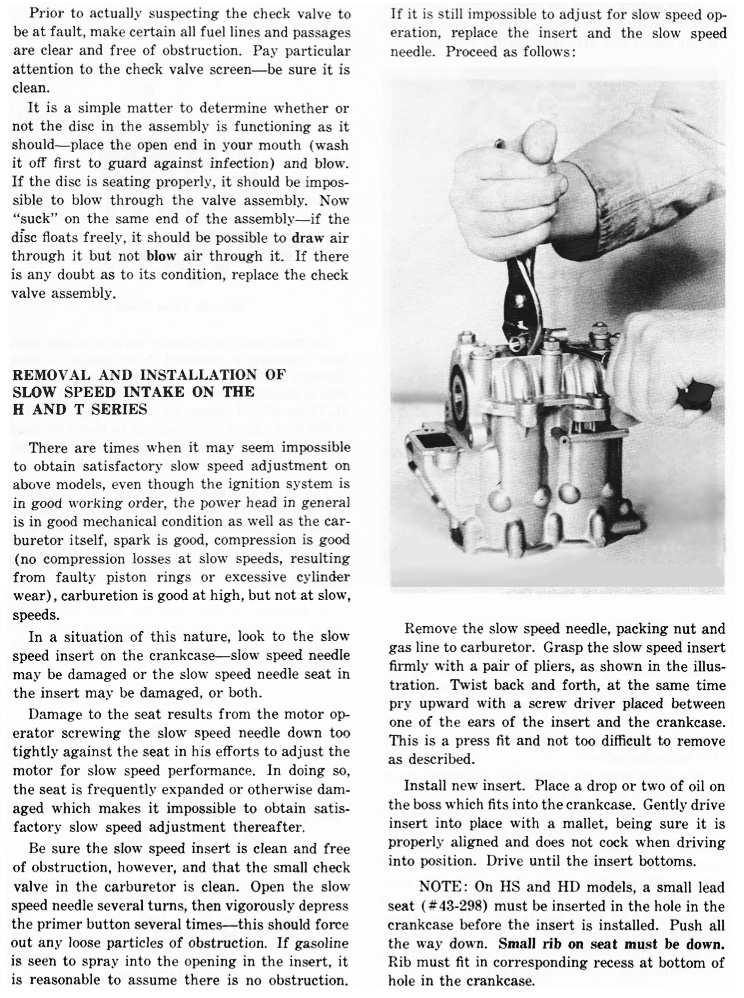

March 25, 2017 at 1:03 am #54833Basically what I know is in the Johnson service manual . . . 😀

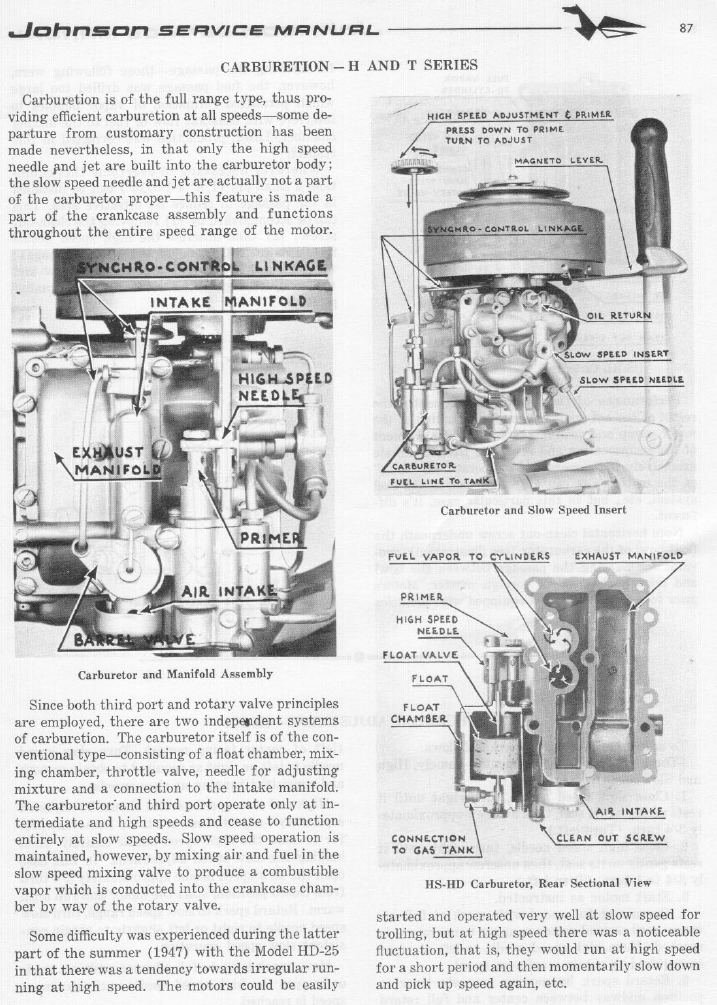

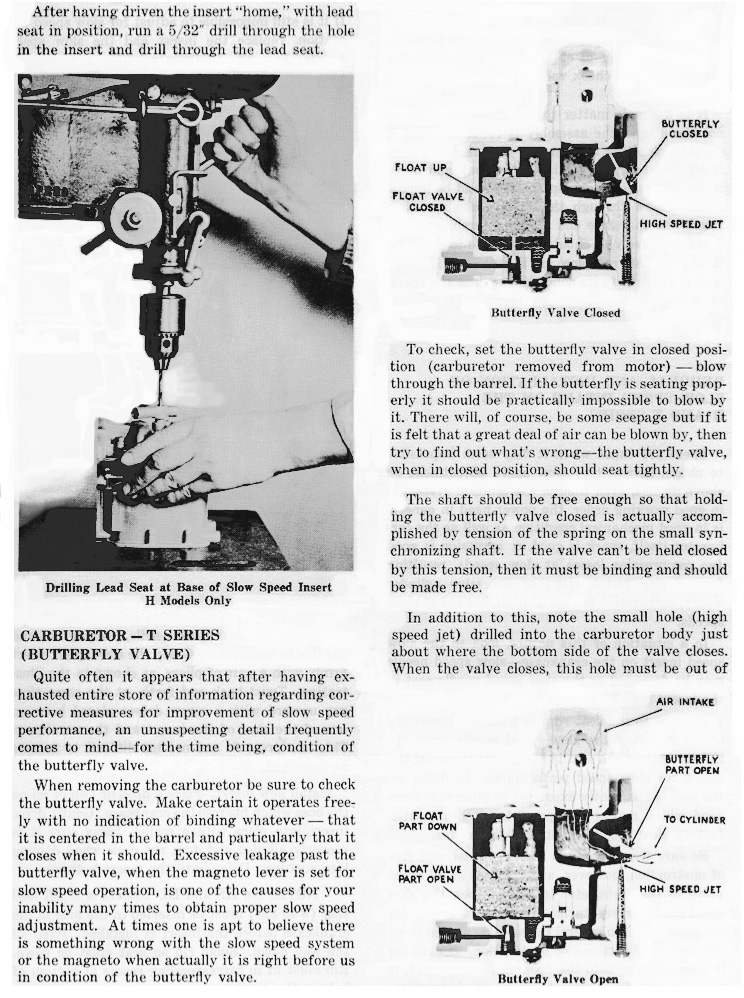

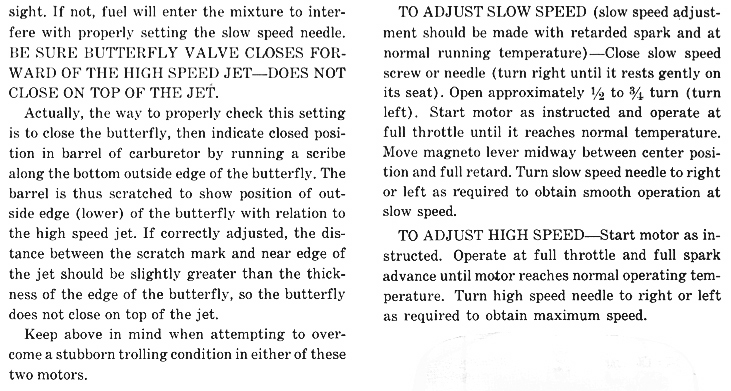

_________________________________________ 1

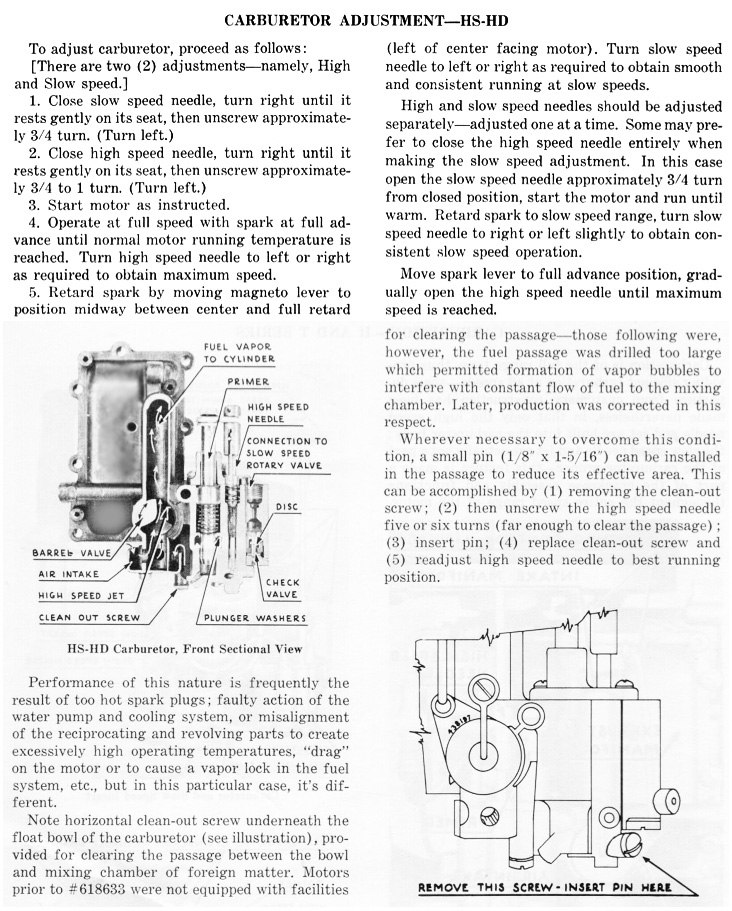

________________________________________ 2

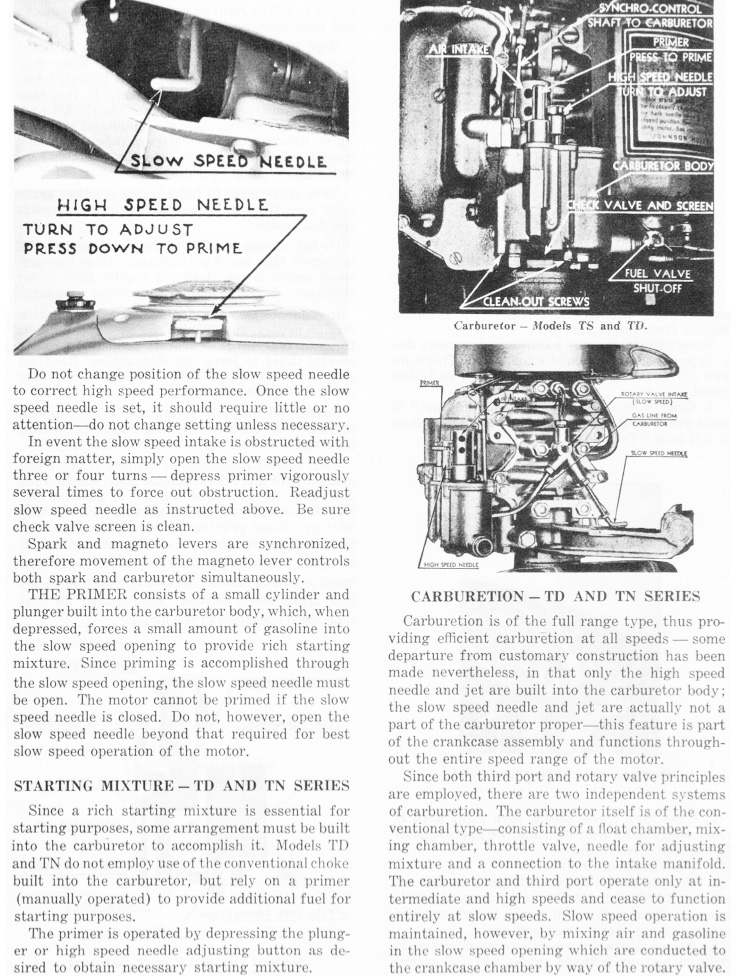

________________________________________ 3

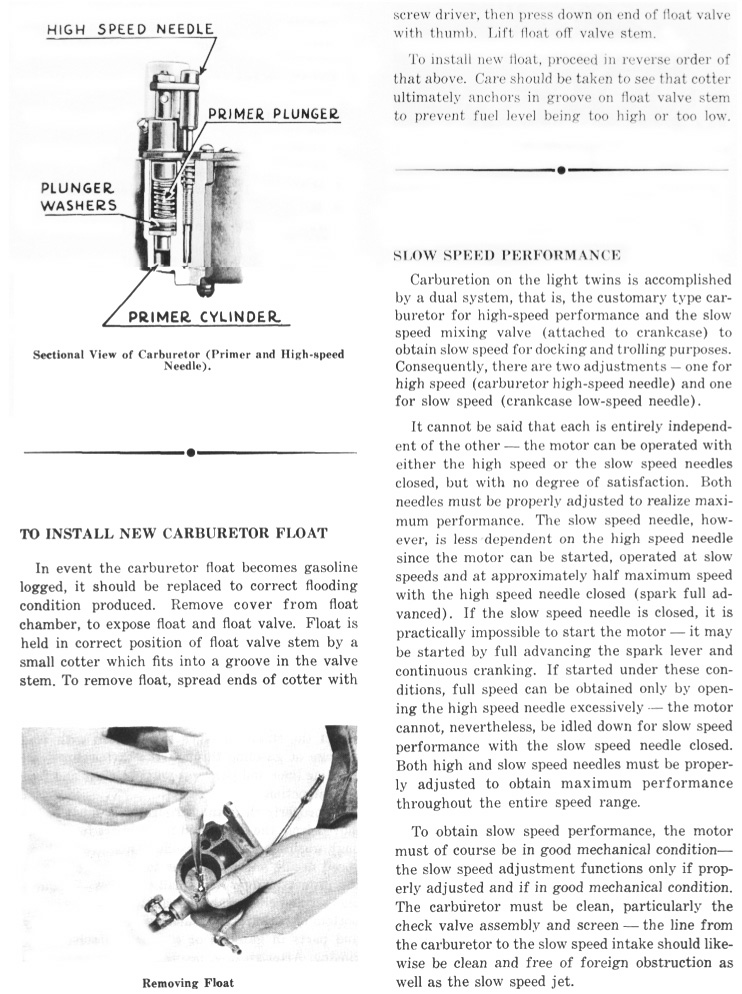

________________________________________ 4

________________________________________ 5

________________________________________ 6

________________________________________ 7

________________________________________ 8

________________________________________ 9

________________________________________ 10

-

AuthorPosts

- You must be logged in to reply to this topic.