Home › Forum › Ask A Member › QD-10 that runs horrible. Expert advice needed.

- This topic has 33 replies, 10 voices, and was last updated 5 years, 9 months ago by

retiredoz.

-

AuthorPosts

-

July 28, 2018 at 11:47 am #80250

Bob, Thank you for posting that. I had never seen that in the operating manual. It is printed on the front of the cowl of my 1954 QD-15 though. I did read that somewhere. There may have been a service bulletin, but I certainly do not know that for certain. Other than the wider bearing on small end of the rod and then needle bearings on the wristpins, there is very little difference internally in the QD line. These early ones came with a 6 gallon suitcase tank and those did not (or at least I have never seen an original that did) have mixing instructions on the tank. The QD-16 came with the more common 6 gallon tank which displayed mixing instructions as 1 quart of oil to 6 gallons of gasoline (24:1). It also says for mixing smaller quantities to mix at 1/2 pint of oil per gallon of gasoline (16:1).

I do stand corrected, however, about the factory recommendation for mix ratio for the early QDs. Being that there is essentially no difference in internal construction I do not believe there is any problem with running any of them on 24:1 using TCW3 oil. That apparently is not the original factory recommendation though. My error. 😳

-BenOldJohnnyRude on YouTube

July 28, 2018 at 12:56 pm #80252Ben since it’s got the same internal construction as the later QD’s I’m going to run from now on 24:1. Makes my life easier not having to switch tanks for my 58 QD.

I’m glad we had this discussion, you saved me some $ on oil.

Thanks,

Bob DJuly 28, 2018 at 1:24 pm #80255While I don’t put lots of hours on any of my motors in any year, I have always run my OMC 10s on 24:1. It is entirely possible that not everyone will agree with me on this practice.

I believe the most important thing to remember when operating a pre 1961 10hp is to make sure you are not overloading the motor. I have been told it should be able to turn around 4500 rpm at WOT. If it is only able to turn 4000rpm or less at full throttle that can cause preignition at full spark advance and the preignition is harmful to the engine. It is this that tends to hammer out the wristpin holes in the pistons of the 10s with the small wristpins. This was much less of a concern once the needle bearings were used on the wristpins.

-Ben

OldJohnnyRude on YouTube

July 29, 2018 at 1:39 pm #80316The best clue you gave was the high speed adjustment not having any effect. I think either the nozzle gasket is missing or leaking, or your float level is way too low. I worked on a 15 hp for a friend that acted similar to yours and found the float installed upside down. The fuel level in the bowl was only about 30% of what it should be. I have and run a QD-10 so I’m aware it shares no parts with the later motors but I think the carb design is similar enough.

July 29, 2018 at 9:27 pm #80339I watched the video and you are not adjusting the high speed needle valve while under load on a boat. To adjust the HSN, loosen up the bracket that connects to the upper rod and use a screwdriver to adjust the valve. The motor has to be running wide open and then start to adjust the HSN, starting off about 1 turn out from seated. Turn the needle about 1/8 of a turn and wait for a response, then another turn until you hear the motor smooth out. Keep turning the screw adjustment in until it leans out (slows down or sneezes) then back out about 1/4 of a turn. Fasten the adjustment bracket back on the needle valve with the upper rod somewhere in the middle of the throw, just in case you have to make further adjustments down the road. Now if you keep turning in the HSN valve and nothing happens, then you have a plugged up high speed circuit somewhere. I am sure others will chime in and give their opinions so be patient and do some research. Pl

PS….I have adjusted motors in test tanks and you can get close, but there is nothing like being on the water, in a boat to do the final adjustments.

July 29, 2018 at 11:17 pm #80345I (still) think the problem would be easier to identify once the butterfly mechanism is freed up. Early on in the video the gap between the follower and the cam is clearly visible when the cam is moved toward ‘fast’. With the follower in the upright position, the butterfly valve is nearly closed, so the engine is in effect trying to run under full choke, which may at least account for some of the voluminous smoke..

July 29, 2018 at 11:42 pm #80348Does anyone know the base setting for the cam and butterfly?

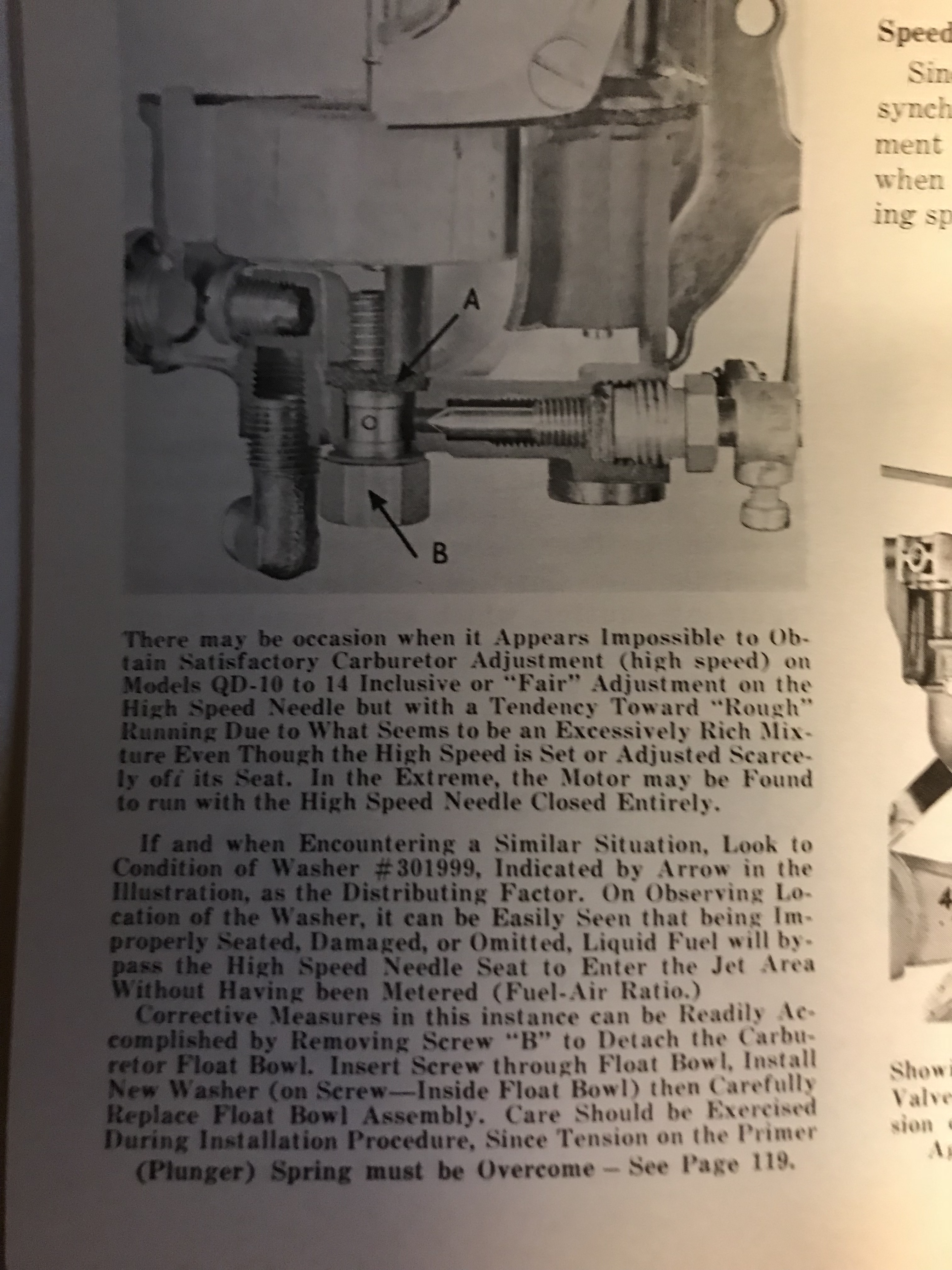

Bob DJuly 30, 2018 at 12:10 am #80350July 30, 2018 at 1:18 am #80355Retiredoz, good find!

Going to check mine. Exactly what I’m experiencing.

Bob DJuly 30, 2018 at 1:25 am #80357Bob, it does seem to match what shows up in the video. There are several pages devoted to that carb in the Johnson manual, I thought I saw an online link to it somewhere on this site. Surely somebody knows ?

-

AuthorPosts

- You must be logged in to reply to this topic.