Home › Forum › Ask A Member › Removing anerobic sealant

- This topic has 12 replies, 10 voices, and was last updated 6 years, 3 months ago by

The Boat House.

The Boat House.

-

AuthorPosts

-

January 17, 2018 at 12:33 am #9019

So there is always lots of chat about how to apply anaerobic sealant. Not so much on how to remove the cured, thin film that it leaves. I know lacquer thinner doesn’t do it. It seems to me that acetone used to work for me but it’s been awhile and I was never quite sure, as that stuff is difficult to see. What do you frequent rebuilders use to be sure it’s all removed?

Long live American manufacturing!

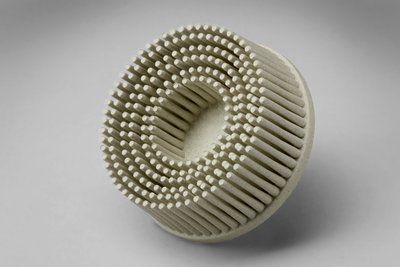

January 17, 2018 at 4:14 am #69793Careful scraping, sanding, and soaking with lacquer thinner is what I used to do until I found these 3M discs at my auto supply. They are used for gasket removal to and come in different colors or grits and the parts guy said to use the white ones on aluminum. They aren’t too aggressive but must be used with a light touch.

https://www.3m.com/3M/en_US/company-us/ … 502&rt=rud

January 17, 2018 at 10:10 am #69798Do not know what brand anaerobic you have to remove but Permatex makes a remover for their anaerobic products.

https://www.permatex.com/products/gaske … c-formula/

I have heard where paint remover works well to remove the anaerobic, never tried it.

If removing the anaerobic from split crankcase design engines (ex Merc Mark 30, Mark 55, Merc 200, etc) that have accurate machined mating surfaces then they are put together (without sealant) and line bored for the crankshaft/ reed cages/bearings/etc to very close tolerance as a matched set you need to be careful to not damage those 2 mating sealing surfaces. Also if resealing these split case engines the mating surfaces need to fit nearly perfect then it only takes a very very thin layer of the anaerobic to do the job. I always check the flatness of the split crankcase mating surfaces and correct any highs before sealing with a very thin dappled coat of anaerobic. My applications of anaerobic on split crankcase engines are so thin that to remove sealant is not an issue with a careful draw scrape with a razor blade.

January 17, 2018 at 10:59 am #69800Thanks for the replies so far. I will consider both, although I have come to expect little help from any product that says, "Low VOC." Overnight, it occurred to me that our detailers have some plastic "razor blades." They look like razor blades and fit into the same tools/holders but are plastic. I am going to try score some of them, along with some acetone. (Yeah, I I know I can’t use both at the same time because the acetone will eat the plastic.) I am currently working on a lowly 3.3 Tohatsu-based "Mercury;" but I am looking to improve my general technique in removing that stuff. I intend to add the motor to my collection when done, as a monument to horrible pieces of crap. I think they used the worst salt water aluminum of any motor ever built. Even some of the crank case screws were beginning to corrode in place. I don’t even know how that is possible.

Long live American manufacturing!

January 17, 2018 at 12:13 pm #69803Im with Mumbles. I use a dremmel tool now. Then clean with acetone.

January 17, 2018 at 11:25 pm #6982810-4 Chris. Be careful though, had the Cops over thinking we had a meth lab between glassing & prepping, Close to infred heat signature,

Now all those neighbors are gone….You know never paid taxes ; > ) !! Not to bring up neon fall-out 2. Many are nuts!

JeffJanuary 18, 2018 at 3:01 pm #69856If it’s that black irremovable stuff, I got some off of my TBird trunk under an ugly antenna with Goof Off and a lot of rags and elbow grease.

A slow process but it came off clean. Had tried all of the solvents mentioned above with no luck. Also tried Goo Gone. Good luck.January 19, 2018 at 12:31 pm #69905I’ve always used Berryman B12 carburetor cleaner with a razor blade… I always drag the razor blade backwards though,

to not nick up the mating surfaces.January 22, 2018 at 11:05 pm #70062This is an important step for sure, and a difficult one for sure. That thin film of sealer left behind is impossible to see but definitely enough to shim the crankcase halves apart and create leaks…

The OMC gel seal remover is potent stuff but does the job. OMC even recommended using a black light to check the halves to ensure all the old gel seal film had been removed….January 23, 2018 at 10:54 am #70078Now we’re talkin’. I don’t ever remember either of those two ideas. I guess I was sleeping at the seminars or skimming the manuals too fast! I am going to look into both of them. Thanks!!

Long live American manufacturing!

-

AuthorPosts

- You must be logged in to reply to this topic.