Home › Forum › Ask A Member › Thin Gasket Material?

- This topic has 19 replies, 13 voices, and was last updated 6 years, 3 months ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

January 14, 2018 at 3:30 pm #9003

What all are you guys using for "thin" gasket material?

The 1940 Sportwin I’m working on has cylinder and

crankcase gaskets .012 thick. The last time I had this

problem I ended up using a paper grocery bag

and some kraft paper that were .008 thick.

There is some 1/64" gasket material "out there", but

that’s almost .016 thick. Perhaps .004 oversize

isn’t too critical regarding compression, but still

maddening that I can’t find what I want.

If grocery bags are used, do you treat the paper

with grease to make them more resistant to

deterioration?

Last time I bought some thin material, it was Karropak,

and it turned brittle and would crack easy while

cutting out a gasket.

Thoughts?

Thanks!Prepare to be boarded!

January 14, 2018 at 3:37 pm #69672I use the stuff from Napa, 1/32 thick, never worried about what it did to compression since it was not used on a racing motor…I will admit, it might cause issues with exhaust bolt up on opposed twin motors so beware of that.

http://www.richardsoutboardtools.com

classicomctools@gmail.comJanuary 14, 2018 at 4:44 pm #69673Even though I get 1/32" as about .031", are you keeping in mind that it crushes when you tighten the parts together? I mean, if you mic out your old gasket as .012", that’s not what it was when it was new….This may be a stupid question; but I had to ask, just in case you didn’t think of it…

As for splitting, a rule I made for myself is to always punch the holes first, then cut. It keeps the material from splitting when you punch too close to an edge.

Long live American manufacturing!

January 14, 2018 at 5:17 pm #69675quote Richard A. White:I use the stuff from Napa, 1/32 thick, never worried about what it did to compression since it was not used on a racing motor…I will admit, it might cause issues with exhaust bolt up on opposed twin motors so beware of that.Learned that the first Ruddertwin I restored. Couldn’t get the damn exhaust on after I installed the jugs! Too thick a gasket.

January 14, 2018 at 5:36 pm #69676quote Chris_P:quote Richard A. White:I use the stuff from Napa, 1/32 thick, never worried about what it did to compression since it was not used on a racing motor…I will admit, it might cause issues with exhaust bolt up on opposed twin motors so beware of that.Learned that the first Ruddertwin I restored. Couldn’t get the damn exhaust on after I installed the jugs! Too thick a gasket.

Same motor I found out on…LOL

http://www.richardsoutboardtools.com

classicomctools@gmail.comJanuary 14, 2018 at 5:42 pm #69677Napa and almost everyone else has gone to Fel-Pro gaskets….back in the day, when I had parts stores (and hair…) I sold Victor. Victor had some really nice stuff that didn’t compress much in a variety of thicknesses called "Victolex" if I remember correctly. Usta’ use it to make base gaskets for my Rotax motors when I was racing sleds…..we did some tuning voodoo with port timing with different base gasket thickness. It may still be out there….

Jim

I say "pardon me" a lot. I had a 20H, then raced open mod sleds.

January 14, 2018 at 6:39 pm #69678Thanks for the replies. I found some Mr. Gasket 9610MGR

that says 1/64" or .015 thick. One comment

on Amazon says it’s actually .012 thick.

Either way, I’m going to call it close enough!Prepare to be boarded!

January 14, 2018 at 8:45 pm #69683Punch holes first is good advice.

Cut out inside as required next.

After installing gasket trim the excess from exterior.

It is a good practice to cut the blank large so you will not be punching or cutting near an edge.

Thickness of gasket stock does not seem to matter to those who sell gasket sets..

They measure all over the place when checked with micrometer.

Gasket material at auto parts stores seems often to kept "in back."

Ask the clerk to bring out what they have.

Usually they have more than one thickness on hand.

I have had no luck finding suitable material to make heat resistant gaskets,.

Those I have to order as NOS.

Heavy duty paper bags are about the right thickness for water pump to gear housing gasket

used on Early Kiekhafer outboards. Grease the paper before installing.

An antique outboard may have leather seals which also can be made with punch and a little

imagination. Save leather scrap for a new purpose.

The $5 punch sets are good values for the money.

Punch will cut gasket cleanly if you use with end grain cutting block.

Maple is wood of choice. Other wood will work. Important thing is end grain that lets

knife edge of punch to go clear thru the gasket into the wood.

Louis

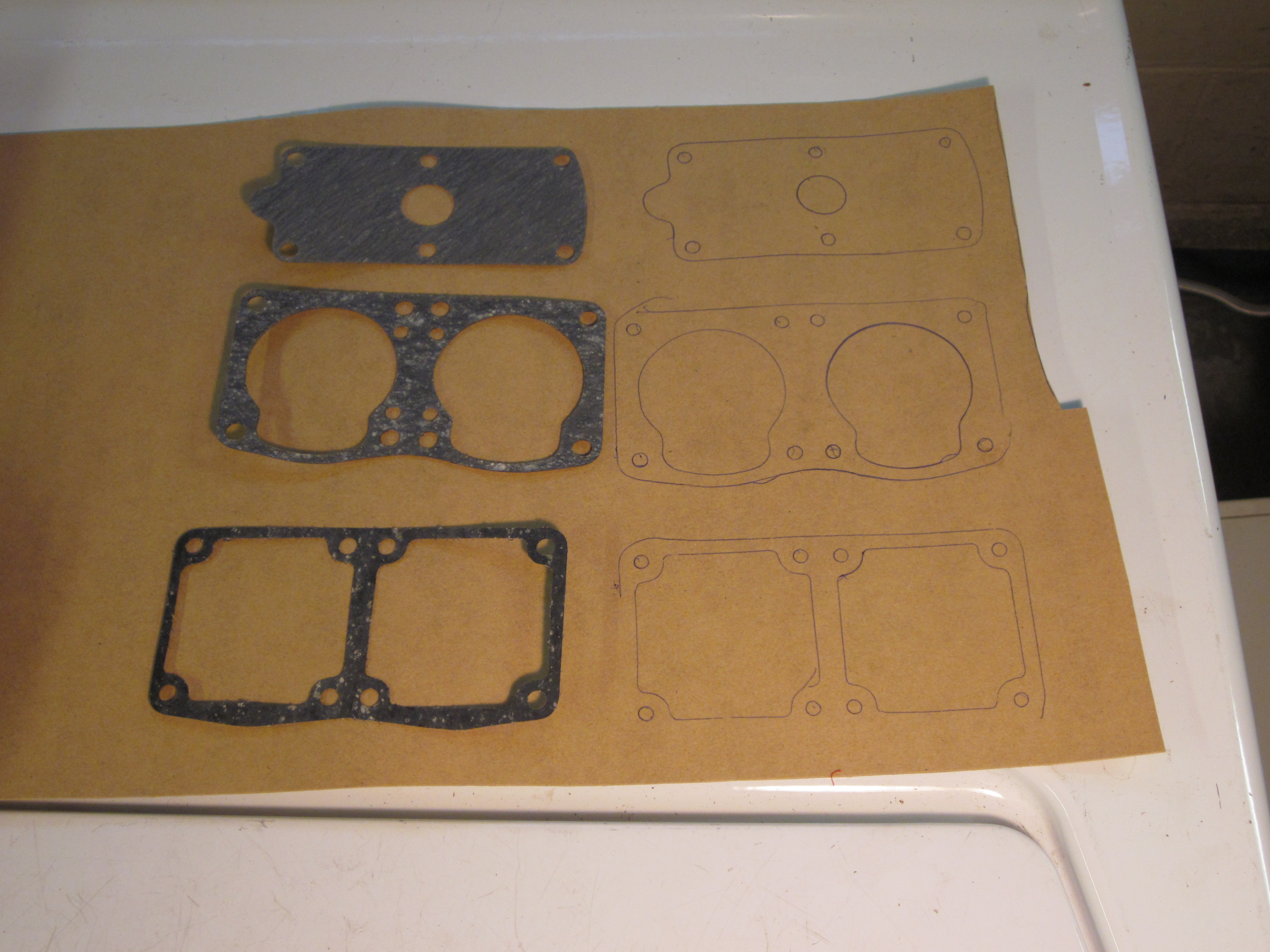

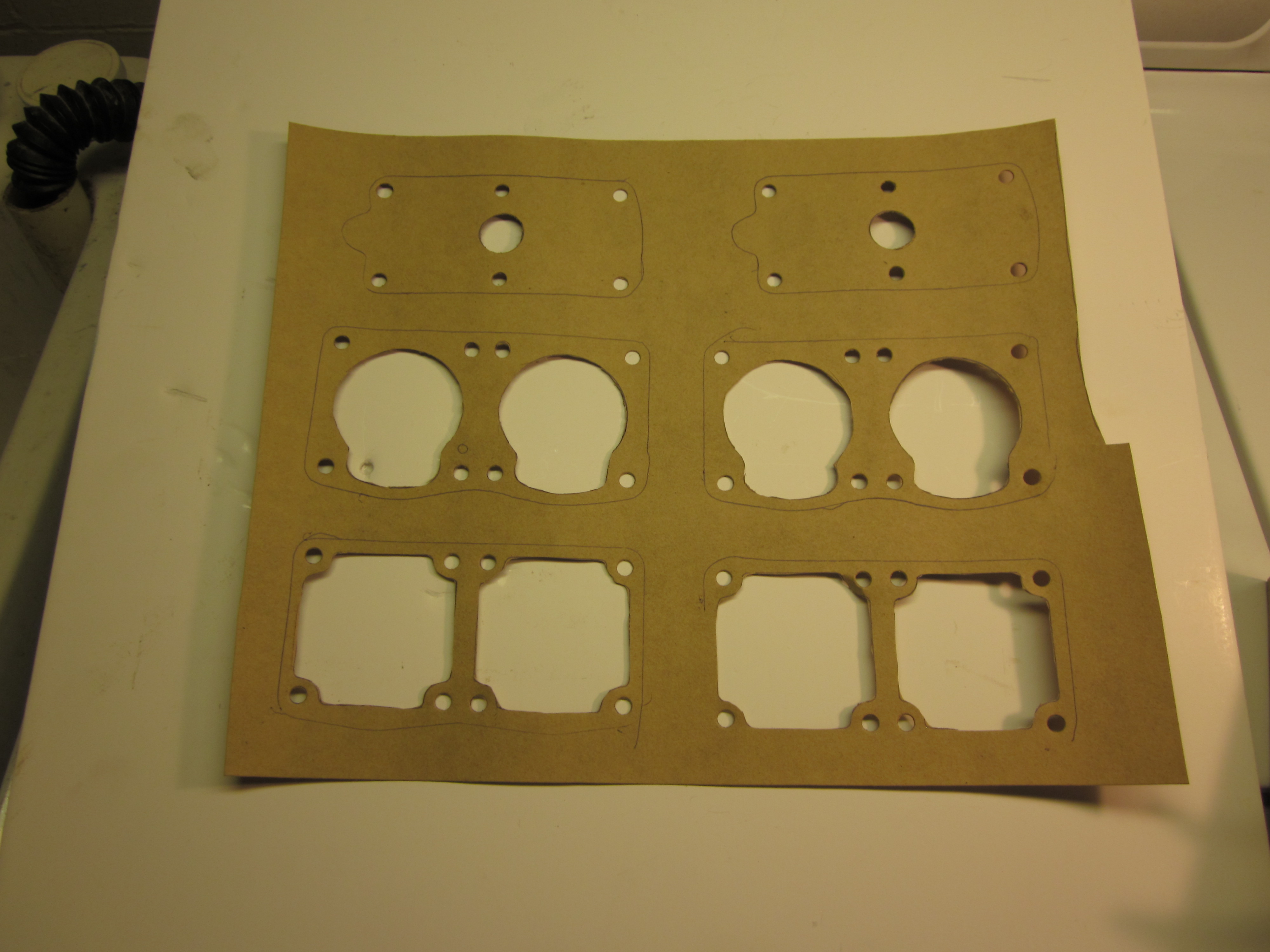

.January 15, 2018 at 1:27 pm #69704January 15, 2018 at 1:42 pm #69705Nice work on the gasket making. I like the big wood block too, great idea.

-

AuthorPosts

- You must be logged in to reply to this topic.