Home › Forum › Ask A Member › Think I ruined my RD-23 lower gear case housing

- This topic has 16 replies, 9 voices, and was last updated 6 years, 3 months ago by

marksoldcresty.

-

AuthorPosts

-

January 3, 2018 at 3:14 am #69213

I’ve used a propane torch to heat the housing from the outside to expand the housing, not the brass, and it definitely has helped me on a couple of RD housings, but you have to heat a long time, as it is somewhat like trying to heat a heatsink, and propane torches aren’t all that hot. I’ve yet to scorch the paint doing this.

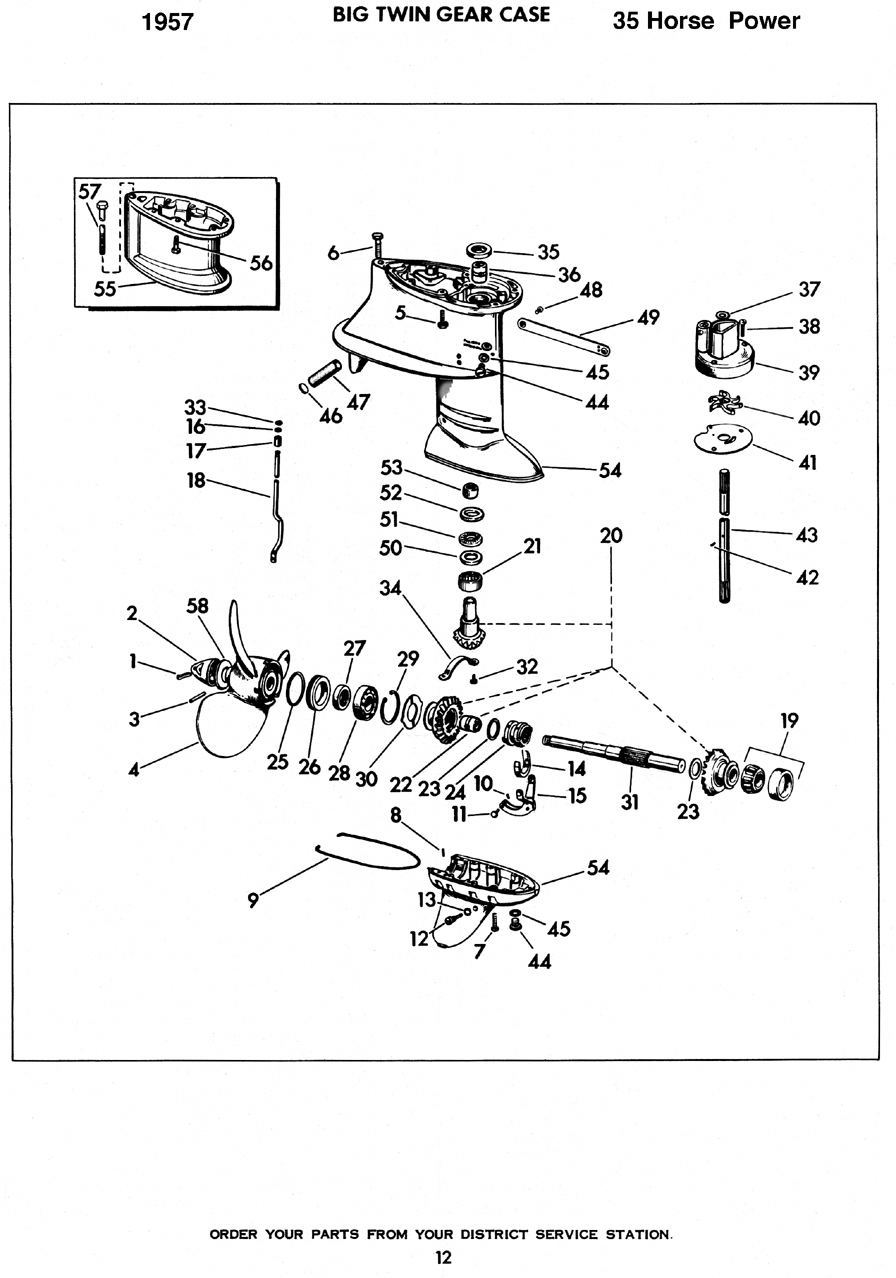

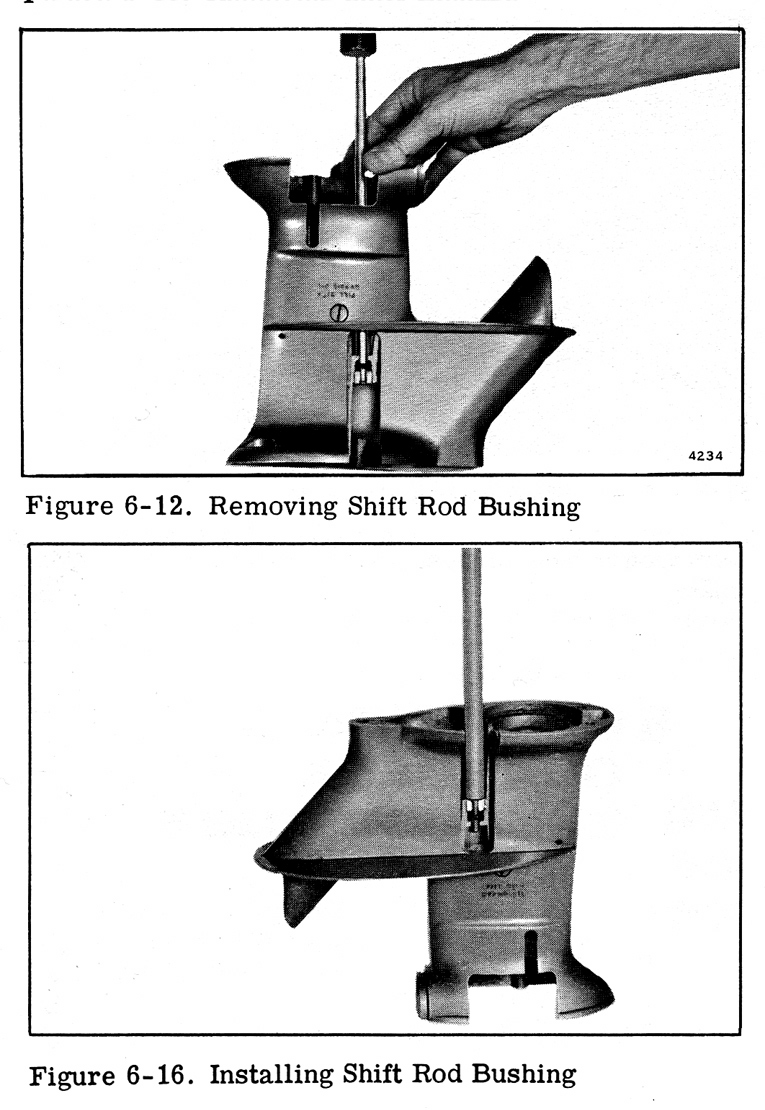

DaveJanuary 4, 2018 at 2:55 am #69239The 40 horse RD-23 has three parts to the shift rod seal. The top part (33) holds the "O" ring seal in place. It is driven up toward the water pump to free the "O" ring seal. In any case the gear case must be split to remove the shift rod. If a threaded rod is used, it must be used to pull the top piece out. . . 😉

January 4, 2018 at 4:08 am #69240

January 4, 2018 at 4:08 am #69240Garry & Frank,

Every day I wonder how is it after the storm? Pull the part but a replacement bushing available. I remember getting thurst washers made 4 old hydromatic trans 2 coupling second gen.January 6, 2018 at 3:53 am #69315Thanks for the parts break out, Gary! I received the bushing and miscellaneous parts today for the gear case. I’m back to scratching my head, again, LOL 😆 after my failed attempt to remove the shift rod bushing gasket. I’ve made a few futile attempts to snag, gently scrape it out with a long skinny screwdriver without marring the bushing bore. I’ll wrestle it out one way or another tomorrow.

January 6, 2018 at 11:45 am #69324I like to use a long dental pick to remove the washer (seal) from the housing. You can buy a whole set of those at Menards, Lowes, etc pretty cheap. They are as handy as a shirt pocket around the shop. Put a little grease on the new O-ring before installing…this will prevent the shift rod from scratching up your new O-ring when you slide it through.

When the day comes that you reseal a larger Johnson or Evinrude gearcase, those picks will come in handy!January 6, 2018 at 12:05 pm #69326Lest there be any confusion, on the RD there is a fat o-ring that fits into a recess in the brass bushing, AND a gasket washer that goes into the housing, before the bushing/o-ring assy. This is different then the smaller motors, which do not use the gasket washer. That gasket washer can be a real bugger to dig or scrape out because it almost seems to grow to the aluminum.

January 6, 2018 at 11:53 pm #69352FrankR amen! Some where hidden in fine print in Webster’s Dictionary under the word "bugger" is, "Term used to describe RD series shift rod bushing gasket." What a PITA it was to remove the material out of the bore. Found what helps the process was using shots of carb cleaner in the bore to soften up the gasket as I scraped it out with a LAS.

(Long A** Screwdriver) -

AuthorPosts

- You must be logged in to reply to this topic.