Home › Forum › Ask A Member › Backfire/misfire thru carb

- This topic has 105 replies, 9 voices, and was last updated 1 year, 10 months ago by

Beno.

Beno.

-

AuthorPosts

-

September 7, 2020 at 5:36 am #213704

OK, well I can’t imagine why you would have to modify the sensor coil clamps, the one clamp that I saw looked like the correct clamp…Will not argue with success though…

These engines are pretty cold blooded until they warm up, and the turbo jet set up probably doesn’t “load” the powerhead the same way the old outboard unit did, exhaust back pressure is different also. Does it idle OK once warmed up? I would put the rig in the water and try it before getting too concerned. Did you drill the heads for the oultet nipples? Looks like that exhaust elbow relies on some of that water to help cool the exhaust.

Finally, please remember that this engine does not have the oiling system, so you will need to advise the new owner, perhaps put some sort of placard near the fuel fill. It is easy to understand how easily it could be to “asssume” this rig has oil injection and ruin the powerhead quickly….September 7, 2020 at 5:25 pm #213738ok Sea trials have commenced. First I ran into a problem (and fixed) with the starter solenoid which I wont get into right now.

I did not drill ,tap or modify the cooling system at this time.I will mark the fuel inlet about mixing oil.She starts and idles at cool temp, and off it goes! 140hp in a 15′ boat, lookout. I put super high octane in and I’m running the tcw3 at 32 to 1 for the moment.

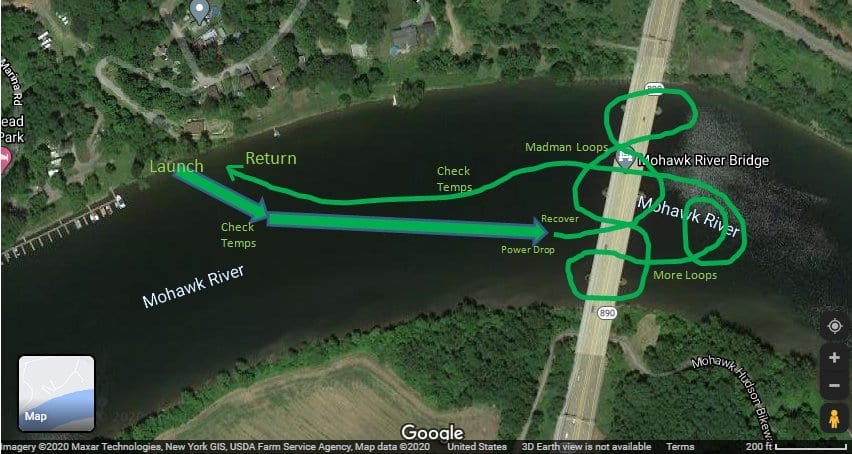

Ran awesome for about 1000feet, then the power dropped, then came back.. did a few madman loops around the bridge pillars and came back. More Power randomly drops. but comes back.

got the laser temperature gauge out, the top of the cylinders topped out at 145degrees, The Crank area in the engine center below the flywheel was significantly higher 179+ deg

I never got a reading above 200 anywhere. the muffer assembly never went over 140 degreesafter the run and at full temp, it just will not idle for long. it dies after a sec. then won’t restart without being choked. (since my switch is broke and won’t run the electric choke, (new ignition switch on order) I have to open the hatch and do a manual choke.

but the most significant thing is the sticky trigger plate is back!.. but only for the last .75 inches of the travel of the plate. the spring coiled around the pivot that makes the spark advance isn’t strong enough to overcome the last 3/4 inch.. weird. It was perfect when I re-assembled! (Im going to see if it works right again after it cools off?!)

solve 2 issues then 2more pop up!

September 7, 2020 at 5:51 pm #213748ok Sea trials have commenced. First I ran into a problem (and fixed) with the starter solenoid which I wont get into right now.

I did not drill ,tap or modify the cooling system at this time.I will mark the fuel inlet about mixing oil.She starts and idles at cool temp, and off it goes! 140hp in a 15′ boat, lookout. I put super high octane in and I’m running the tcw3 at 32 to 1 for the moment.

Ran awesome for about 1000feet, then the power dropped, then came back.. did a few madman loops around the bridge pillars and came back. More Power randomly drops. but comes back.

got the laser temperature gauge out, the top of the cylinders topped out at 145degrees, The Crank area in the engine center below the flywheel was significantly higher 179+ deg

I never got a reading above 200 anywhere. the muffer assembly never went over 140 degreesafter the run and at full temp, it just will not idle for long. it dies after a sec. then won’t restart without being choked. (since my switch is broke and won’t run the electric choke, (new ignition switch on order) I have to open the hatch and do a manual choke.

but the most significant thing is the sticky trigger plate is back!.. but only for the last .75 inches of the travel of the plate. the spring coiled around the pivot that makes the spark advance isn’t strong enough to overcome the last 3/4 inch.. weird. It was perfect when I re-assembled! (Im going to see if it works right again after it cools off?!)

solve 2 issues then 2more pop up!

September 7, 2020 at 6:00 pm #213751OK, well you have hit on another possible cause for a funky idle. The two piece throttle advance lever stays rigid until the sensor stop hits the rubber WOT timing stop. Once this happens, the lower portion of the arm is able to continue its travel forward, under spring tension, to advance the carb butterflies to their WOT position. Perhaps the two piece throttle arm is binding where the two pieces are joined together and swivel, there should be a plastic bushing between the upper and lower throttle arms. If the two pieces are binding and not able to rotate freely/independently (except for the spring pressure which is great), the symptoms will be:

The engine will idle and accelerate normally, the problem develops when the throttle is retarded from WOT. Because the pieces are binding together, the timing will retard first even though the carb butterfles are still supposed to start closing first. Once the throttle is reduced, the timing will be retarded to idle even though the throttles are partially open. The engine will spit lean and probably die. This issue will not cause the engine to surge though, I’m guessing you have a partially plugged high speed jet or an ignition issue.

I like the idea of mixing at 32:1, this jet application is a quite a load. Using the premium fuel is a great idea also, that old 140hp powerhead is relatively high compression, and probably won’t last long on 87 octane…September 7, 2020 at 6:52 pm #213756I checked and now that the engine has cooled down the ignition plate has freed up again. Go figgure that one!

Im off to get some dry gas, a fuel filter and some fuel hose..

My posts seem to be dissapearing and reappearing. Not sure. Good ol wordpress.

September 10, 2020 at 6:14 pm #214222Ok, sea Trials are doing very well.

I started it up and it was clearly missing a cyl or more.. I ran it a few minutes and turned it off.. I got the laser-temp-shooter out, spark plug temp was 131F-131F-130F-107F deg

I pulled the colder plug and it was totally coated in 2cycle oil. (someone pu NGK polar plugs in this thing??) polar plugs are neat but once the oil pools in them. no workie!!!

clearly I’m running too much TCW3…I had 6 gallons of 93octane in the gas tank at 30:1 mix, so I went and added 2 more gallons of straight gas at the pump, that should push it down to around 40:1

I replaced the plugs and put her in the water. I started it up, it wasn’t very happy… I kept it going with choke and high idle then got it above 3000 RPM and it suddenly took off, and left a big cloud of blue smoke behind me! off I went.

(Bonus feature today is I realized that the tachometer on the dash is functional! who would have guessed.)

More loops close to my launch trailer today, since I have a 2008 boat sticker…. I’m So paranoid of the sheriff on the water..Max RPM seems to be attained at 5800RPM. is that sound right? feels like a rpm limiter is stopping it.

Anywhere above 4500 rpm the boat runs almost flawlessly, occasional miss (hard to hear) and Powers around and Goes like a rocket.

4000-4500 RPM: a bit erratic,kinda holds its own… rpm fluctuates and slight powerdrops off randomly tho.. within tolerance at this budget.

3000-5000 RPM: Can’t get it in this range while slowing down, it drops from 4000 right down to 2900ish… drops like a stone.

1250-3000 Rpm: not bad today.. holding it’s own.

below 1250: choppy, kickbacking. unhappy motor. stalls within a few seconds.I freed up the ignition trigger pretty well at this point.

Ok, questions:

Whats the proper low idle rpm number?

is 5800 a good/safe top RPM?

Should I just adjust to 1250 rpm idle and be happy?September 11, 2020 at 9:24 am #214419OK, this is the third time I have typed out a reply, none of them posted….I guess I wasn’t logged in for my last attempt….

So, will be brief

The turbo jet has a relatively high idle RPM, so 1000-1250RPM is fine for idle speed. Trying to lower the RPM will usually result in that clunking and banging your described.

The original powerpacks for this engine had no rev limiters, but who knows what they may have been replaced with. Take pictures of any white ID numbers on the packs.

5800RPM is OK for WOT RPM, keep in mind your tach reading may be inaccurate.

I would stick with the 30:1 mix and premium fuel, this older high compression 140 will need all the help it can get to survive this harsh turbo jet application. The puffs of blue smoke were probably due to a misfiring cylinder coming back to life burning off all the gas/oil in that cylinder.

You have worked hard to revive this unit, but I would sell it off once it is working OK. Unfortunately, the Turbo Jet was not one of OMC’s better products.September 11, 2020 at 2:58 pm #215596Ok. Sorry about the posting issues. I work on WordPress systems myself and its chukFul o Bugs. Just like Joomla and Drupal. But wordpress is winning the CMS battle by far so we all will need to live with it.

Ok ill post the spark plug pics here, ive got new coils to install. And i have to find and install better clamps for the cooling hoses coming out of the lower head tubes they’re leaking.

Ill be able to test more maybe wednesday when i get the boat stickered up. In the meantime ill finalize the fuel hoses and replace the keyswitch and try to get the lights, choke, and blidge pump going.

I really wonder if the turbojet system is all that “hard” on the engine. Its just an impeller. Granted there is no neutral, so youre always starting engaged.. but it seems to be ok. But ill probably sell it next spring

I have 2 more boats to salvage anyway.

September 11, 2020 at 7:00 pm #215617Those surface gap plugs usually look crappy like that…But, on this older higher compression V4, you need to use them…The J gap plugs are too hot for this engine/application… The turbo jet usually has two speeds, idle and WOT. Whereas a conventional propulsion outboard boat can usually be throttled back a bit to a reasonable cruising RPM.

July 1, 2021 at 12:52 pm #241689Sea trials have re-commenced for the year. see video.. 140hp at .30Over

https://drive.google.com/file/d/10jUDLGclaTwY8u28IOFD29wfwyUpiXYw/view?usp=sharing

what’s the best way to attack this fuel gauge not working… start by checking for 12v at the fuel sensor top?

-

AuthorPosts

- You must be logged in to reply to this topic.