Home › Forum › Ask A Member › Mcculloch 4hp no start

- This topic has 132 replies, 16 voices, and was last updated 7 years, 1 month ago by

joesnuffy.

-

AuthorPosts

-

April 24, 2018 at 7:03 pm #74674

Where did you look ? You need to pull the powerhead and check for carbon buildup around the exhaust ports. I’ve actually seen that (once) on an air-cooled lil Elgin. Wasn’t bad enough to keep it from running, but it wouldn’t stay running very long.

I’ve lost track of this thread, but did we decide you don’t have any broken reeds ? Might be worth a look.April 25, 2018 at 12:39 am #74694If your AC plug is a 46S, it’s the equivalent of a champion J18y. If it works, I’d just stay with it. I don’t think the plug is your problem…

April 25, 2018 at 1:59 am #74701April 25, 2018 at 2:03 am #74703I pulled lower unit completely off and then pulled exhaust baffle off. It had about a 1/8th inch carb build up all over but was not clogged. I got a screwdriver and scraped it all off and wiped it out. The put lower housing back on (minus the gear). I guess I can pull it again and use my Dremel to get everything out.

The spark plug hole ended up getting stripped out, so I put a insert in it today.

I have never had to do points on a single cylinder outboard before so I looked it up to make sure there is no unapparent timing procedures and there wasn’t. Set timing at .20 when points are on top of lobe.

I have a second carb that I robbed from the ted Williams (since it’s seized up) and I’m going to find be another carb kit, I guess, since the one I just put on didn’t work out. I purchased a wall to kit, so I didn’t go super cheap or anything. Do these just not hold up to modern fuels?

April 25, 2018 at 12:28 pm #74729Seems you have a challenge getting this motor to run or even hit. I’m guessing it is something simple keeping it from running but its difficult to determine what that simple thing is. We have all been there its no fun but when you finally figure it out its very rewarding.

I have seen those carb bowl seals grow as yours did for years their a real pain. I wonder if a thin o-ring that diameter would work especially just for testing purposes? Napa might have one that would fit possibly even a green colored one that is for fuel. I have read your thread now a few times on this particular engine. I suggest you try and concentrate on getting the motor to run for a few seconds using starting fluid then once you get it to hit and run for like 4 seconds then you can concentrate on the carb and getting that right and keeping it running. My method of thinking on this engine is something is keeping it from hitting and that has to be found first.

Starting with exhaust. I think you said you took off the lower unit and tried to start the engine with it off and it kicked and spit black smoke but did not start. My question is did you take the actual power head off or just the lower unit. Did you inspect where the exhaust leaves the engine cylinder area all the way until it exits outboard??? And did you try and start it with the power head taken off??? If I was working on this engine I would want to make sure the exhaust was clear from the cylinder area all the way out to the point it discharges from the outboard. Many times I will start an engine with starter fluid just to hear it run a few seconds to hear it and determine if it has internal damage before spending money tuning it up etc.

Something simple might also be your points cam is it on the crankshaft with the writing up as in your picture or did you have it off and put it back on upside down possibly??? I’m guessing you did not but I have seen that done also. Did you possibly switch the points cam from one motor to the other since you have several motors are both points cam exactly the same?? One thing you could check as far as timing goes is to rotate the crankshaft clockwise until the points just open then slide a pencil into the spark plug hole to see if the piston is close to top of cylinder. I think you said the timing is fixed so if its fixed the piston should be at almost the top of the cylinder when points just start to open. Its been ages ago like 1978 but when I was a kid like 13 or 14 I was going to vocational school at night to learn how to work on small engines which was my dads idea. Tecumseh used this type of set-up we would put the piston a certain distance from tdc and points gapped at 020 then rotate the ignition until the points had just opened then secure the ignition with a couple of bolts. We always marked it before moving it in case we had to put it back and we only did it on an engine that had a problem. Looking at your pics yours doesn’t seem to be adjustable. What does look to be adjustable is the points. Their not one piece but 2 separate pieces. If you can’t get it to hit what you might try is to take spark plug out rotate the crankshaft very slowly clockwise until the cam should be just starting to push on the points at that time the points should have just opened if not take a screw driver and adjust the points until they just start to open then rotate the crankshaft back around a few times to make sure you got it right don’t be concerned about the point gap just when they open. Take a pencil and see if piston is almost at the top of cylinder when the points just open. Looking at your picture of the points cam their is an arrow head with feathers use them to help judge where the cam diameter is starting to get bigger and should just be starting to exert pressure on the points to figure out when they should just be opening and used to re-check it a few times by rotating the crankshaft clockwise until that point on arrow head and checking to make sure points have just opened and piston is a bit before tdc not after tdc. Once you think you got it right take the pencil put it down inside spark plug hole while rotating the crankshaft slowly clockwise going toward the part on arrow head where points just start to open and stop when points just open pencil should be still coming out of hole not going back into the hole it won’t be precise but you will at least know its not after tdc.

You said you had the reed valve assembly off the engine and made gaskets but you made no pictures of that process. It would be nice to see the gaskets you made and the reed assemblies to let folks here have a better understanding. Also pictures of the exhaust and anything else is very helpful. Pics are worth a thousand words.

I would re-mount the carb leave the gas valve turned off to carb for all testing and spray some starting fluid in throat of carb see if engine will hit and stay running a few seconds if not its not the carb as main problem start looking for the reason. I would start with the simple things first such as re-check the compression on the engine. Re-check the reed valves assembly. Check to make sure points cam mounted in right position and points are still at 020. With power head off make sure exhaust is clear on power head. With power head off using the starting fluid only try and start power head by having someone help you hold it to see if it will start for a few seconds if it starts the exhaust restriction is below power head. Possibly a leaking crankshaft seal on the top seal or bottom seal or both. Check out this video. https://www.youtube.com/watch?v=AWuRd7yjHlQ

I hope this helps, Take plenty of pictures their free and very helpful.

Joe

April 25, 2018 at 8:30 pm #74766That helps.

The reed valves were clear. I just cut a new gasket out of gasket paper and reinstalled. I had the head assembly off when I checked the exhaust.

I have not had it do anything for me thus far. No kick, no sputter, nothing.

I’ll rip into it and get back with y’all in a couple days.

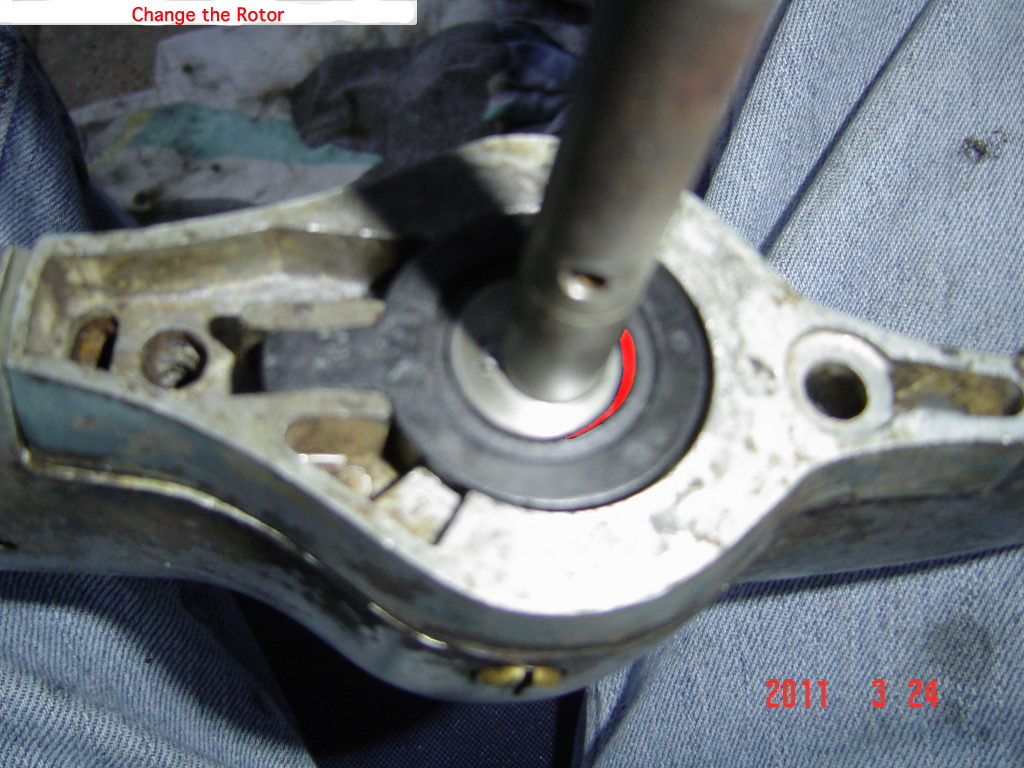

April 26, 2018 at 1:43 pm #74811Here is what I pulled off and the exhaust port is clean enough to breathe properly.

I put it all back together after a little more cleaning and check compression. Compression is at 80 (give or take 2-3), I still have good spark with new points and condensor. However, even with using starter fluid, I can’t get a put or pop or bang. Nothing. Not sure what’s wrong.

April 26, 2018 at 7:04 pm #74824OK, let’s get really desperate : Pull the plug, squirt a tad of starting fluid into the cylinder, replace plug and crank. If it snorts or fires, the problem is in the fuel delivery. If still nada, your timing must be off, go back and check Joesnuffys excellent suggestions. I think his crank seal idea is probably right on, it’s a typical result of running your ‘air-cooled’ engine without a functioning impeller…

April 26, 2018 at 11:09 pm #74832April 26, 2018 at 11:32 pm #74835That looks like a water pump rotor to me . . . . 🙄

-

AuthorPosts

- You must be logged in to reply to this topic.