Home › Forum › Ask A Member › ‘62 5.5 evinrude

- This topic has 32 replies, 14 voices, and was last updated 5 years, 7 months ago by

fleetwin.

-

AuthorPosts

-

July 21, 2018 at 4:06 pm #79844

Just re reading the replies again. I’m doing this on my phone and I’m hitting the time of life where I need glasses. Fuel tank is brand new. Fuel is new. And I mixed a second batch to eliminate the possibilities. Also i misspoke fuel mix is 24:1 That ratio is a hotly contested piece of information. Four things to never talk about. Religion-politics-vaccinations-fuel mix ratios in vintage outboards. I really tried to eliminate the more simple items. In my line of work often diagnostics fall onto finding out what it isn’t first in order to find out what it is. That shock absorber is haunting my thoughts now. I’ll have to find out more. Although I don’t think I can jump a 1/4 with my spark tester. That’s a huge gap. Also coils are definitely new. I did them myself. Had the flywheel off more times than I’d like to admit getting them set in just the right spot. Points were at 020 as per the spec. Checked right before I crumbled and brought it to the mechanic.

July 21, 2018 at 4:07 pm #79845Missing or dropping a cylinder under load is usually caused by a bad or weak spark plug. New NGK B6S plugs gapped at 0.030" might solve your problem. If the condensers weren’t replaced, they should be to with new OMC/BRP 580321 ones to as they go bad over time to.

July 21, 2018 at 4:34 pm #79847As mentioned above a couple of times, please check the "link and sync" of your carb to magneto timing, it can really make a difference and can make a motor act like yours is acting, at least in my experience.

To do this, look on the front of your mag plate, and there should be a triangle wedge bolted to the front of it. It’s the one the carb linkage roller rolls on to and fro when you open/close the throttle. It’s right above your carb.

There is a mark on the triangle piece. It needs to be timed so that the roller is on top of the mark just as your LOWER carb linkage starts to move. It’s the linkage that is connected to the horizonal throttle shaft that goes thru your carb.

There are two 5’16" little bolts under the wedge. Loosen both slightly and move the wedge in/out as needed to get the timing right. One bolt is in a round hole, the other in an elongated hole to create a pivot point and a tightening (set) point. It will take a few setting and tightening tries to get the timing right on.

You can clip something like a alligator (roach) clip onto the actual throttle shaft on your carb for an observation point to make it a little easier to see the carb shaft move to set it to when the roller just reaches the line on the wedge.

If you have any trouble doing this, post back and maybe someone can explain it better.

Check this first before doing anything else… Just like a car or anything else, it needs to be timed correctly to run correctly.

July 21, 2018 at 5:50 pm #79849Where are you in the NE? I am in Providence, but travel back and forth to Logan airport a few times a week…

OK, so I guess your engine probably just sat in the mechanic shop for all that time, the new techs wanted little or nothing to do with it…

Keep in mind that the engine will seem to rev up fine in neutral, even if it is running on just one cylinder….

You had the powerhead off to do the water pump, I’m hoping you got all the crazy lower crankcase seal components back together OK. You mention changing the powerhead bolts, but it sounds like you cut them to length properly…A bolt that is too long could damage the crankcase casting and cause problems…

You can’t really judge spark quality just by pulling it over with the plugs out…Could be losing spark under load at higher RPMs. Those inline neon testers are a helpful isolating a spark problem under load.

Basic sync adjustments aren’t going to affect the engine much at high speeds, but is the carb linkage connected up properly…Advance the throttle to make sure the carb butterfly is opening properly/completely.

Again, something as simple as a bit of water in the fuel tank could be causing this issue. I would tip the tank to one side and try to siphon some of the fuel/oil mix from the lowest part of the tank into a glass container….Let it sit for a bit and see if water separates out…

Finally, you mention that the engine does seem harder to pull over after it quits…Again, are you sure it is not overheating? An engine that is overheating will appear to run normally at high speeds, just bog down and stop/seize up….An engine that does not have enough oil in the fuel mix will do the same thing, except it won’t overheat (at least on the outside where you can feel it). Have you done a compression test…

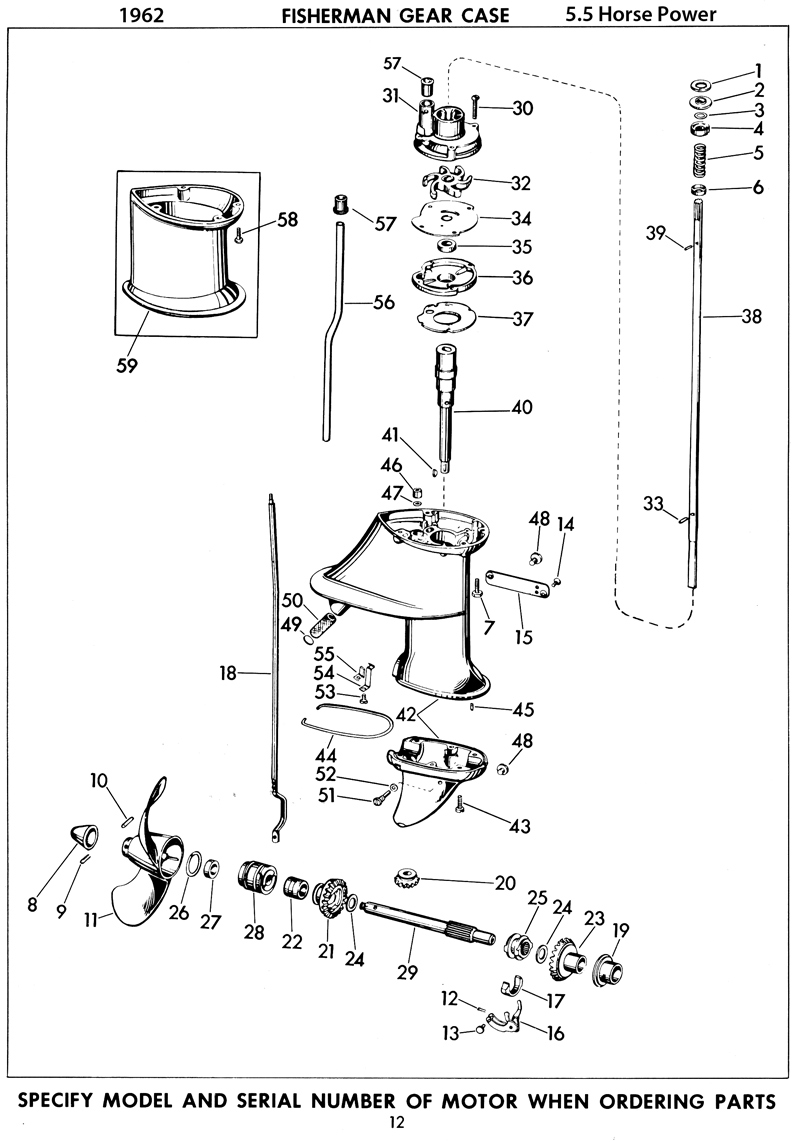

And yes, being tough to pull over can also be a symptom of a binding gearcase shock absorber. But, I don’t want you to pull the gearcase apart until/unless we rule out other more basic issues…You said you changed the gear lube when you had the gearcase off…Was the lube watery?

And yes, you can not see/evaluate the gearcase shock without disassembling the gearcase, or at least prying up the bushing/seal housing underneath the water pumpJuly 21, 2018 at 11:09 pm #79863How are your fuel lines?

The original lines on the motor itself might be affected by ethanol fuel.

Is your tank to motor line that grey line that separates?

Just a couple of things to consider.

Good luck with your motor.Steve A W

Member of the MOB chapter.

I live in Northwest IndianaJuly 22, 2018 at 12:12 am #79867I am on long island fleetwin. Doug thanks for the step by step. Certainly sounds like I can do that. I will give it a whirl and yeah hardly anyone looked at this thing in the shop. They didn’t charge me so atleast they aren’t crooks too. Spoke to my mother about the hours on this thing. According to her. The original owner barely used it. My grandfather got it as a gift from the orininal owner and he never used it then my mother had it and it was a temp motor for when either our 18 or 40 fast twin went on the fritz. So we can ballpark the hours somewhere between hardly broken in and barely used. I will say when I opened it up everything was in fantastic shape. Original coils were intact not split. Wires were still flexible etc etc. I know better. Wires will crack, gaskets will fail, fuel pump probably will leak. Water pump gotta be shot. When I dug in. Water pump was the upgrade pump. Wires were stranded not solid. I just replaced the things that were most likely going to cause headaches. Then got the ignition firing both cylinders. One condenser and points ended up being replaced. Both coils and wires. The plugs probably are original. I’m going to replace them. Eliminate that. I’ll follow Doug’s instructions and see if I’m in time with the cam. Fuel lines are replaced. Hopefully it ends there. I could use a set of those neon spark testers. I’ll pick them up just to verify spark is good. From there it looks like I’m pulling the power head and looking into the shock absorber. Thanks everyone. I’ll keep you guys posted on the progress. With a little luck I’ll be running just in time to winterize it.

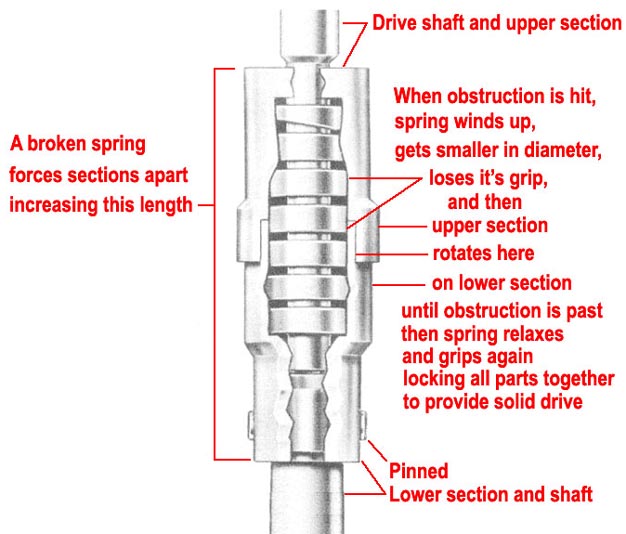

July 22, 2018 at 12:26 am #79868quote Scottshea:Wow! Thanks everyone for the input. If I can answer most of the questions raised. Yes one set of points were replaced. I have checked the spark to ground on both cylinders. They were ok but I adjusted the coils better and got them a little whiter. I’m not sure I have the equipment to synchronize the cam with the carb? If I read that right. The compression was above 80 on a ratty old compression tester. Interestingly the water pump came up. Yes it was replaced. Which is why I went to the Allen bolts. They’re much easier to remove now than the original ones. I don’t recall seeing anything with springs in the lower unit when I had it off. I am assuming it’s simmilar to an pump coupling. They’re in the gear case? I haven’t opened that up yet. But I have flushed and replaced the lower unit oil. I’m not sure how many hours are on the motor it has sat dormant for almost 4 decades. When the motor bogs it really just Peters out like it’s flooding. No unusual shuddering so I don’t think it’s a misfire but it will almost always shut down even if I back off the throttle. Last but not least it does seem to be harder to pull start after she stalls. That is something I did notice but maybe ignored since it could easily be me feeling tired from pull starting the motor while I’m trying to get the tune right. I’m definitely going to give the fuel pump test a try. It’s brand new and shouldn’t be failing but at this point nothing can be taken for granted. Also if I do try and prime the motor while it’s running it does not seem to make a difference. I attempted to keep the fuel bowl full while trying to diagnose this and that didn’t seem to help. The motor does rev on the boat and in the water in neutral. The outboard mechanics who’ve been locally in business for at least 50 years are all out of ‘vintage’ grade techs. Sadly they’re a more rare breed. The young guys just don’t have the feel to tune things anymore. I really don’t think they looked at this motor too hard either. Here in the north east he was handed the motor just as the season was kicking off so honestly it probably has more to do with they can’t charge me too much to fix it since it has little value even if it is running. So sadly they don’t invest the time.Aha!! Seems harder to pull when it stalls. Now we’re getting somewhere. That suggests shock absorber in the lower unit. There is a honking stiff spring inside it and when the spring breaks, the ends ride up on each other, causing it to expand in length and become too long to fit the space it is in.

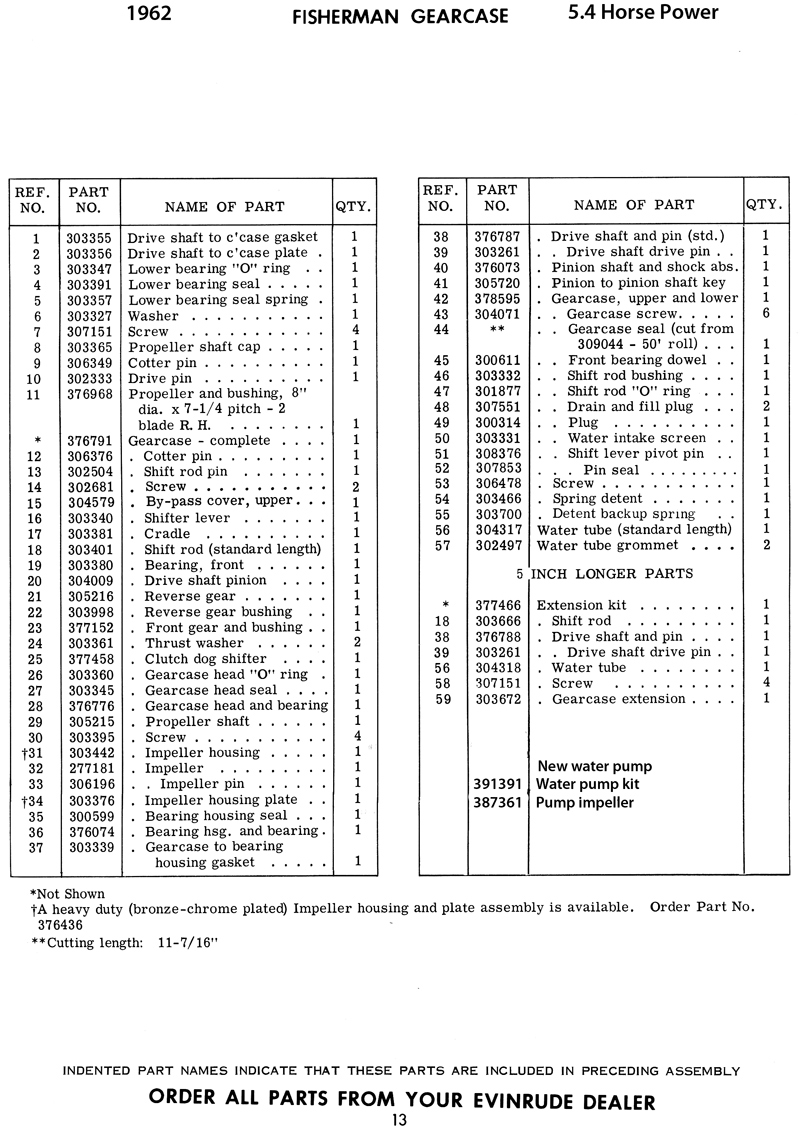

July 22, 2018 at 12:33 am #79869Awesome frank! Thanks for the diagram. I’m going to cover the easy bases the just dig in to the lower unit. This spring available? Or can I visually verify this parts bad? Some people asked for a video. Here is a link. Few useful pics and one video. Also a couple of I’m proud of my project pics. Enjoy.

https://www.icloud.com/sharedalbum/#B12Gf693ZMiIm9July 22, 2018 at 2:58 am #79878OK, well that is a beautiful engine, certainly worth the time and money to get it straightened out. These are some of the best running little engines ever produced, including the smooth four strokes of today…

Yeah, sure doesn’t seem like it has many hours on it…

Again, how did the gear lube look when you changed it? If there was no evidence of water, it is less likely that that shock absorber has "sprung".

Not impossible for sure, but less likely.

Seems like you have ruled out a bad fuel/oil supply..

Looks like the coils have been replaced, but those condensers look pretty original.

Thanks for the video, but it is hard for me to judge whether the engine is running on two cylinders with no load in neutral. So, I would certainly true those inline neon testers…

How do the plugs look? Do both plugs look the same?

You reported that you found the engine had the updated water pump, so it has had some sort of servicing in the past. Are all the lower seal parts intact? This is extremely important, improper assembly/missing pieces to that crazy lower seal set up can lead to water ingestion and powerhead failure.

It looked like the engine was pumping water while you were running it on the flushette, but that doesn’t mean much, the water pressure from the hose can surely mask a cooling system issue.

So, go ahead with the neon testers, they are readily available, do the simple stuff first…

Where on the island do you live? Which dealer/shop did you take it to? I know many of the OMC shops out there…Don

But, like you say, at least they didn’t charge you an arm and a leg, replace a lot of stuff, and return the engine with the same issue….

Labor doesn’t come cheap on the island, so not getting charged speaks volumes for the shop’s integrity….July 22, 2018 at 5:54 am #79880It is a bad sign if the top of the 376073 shock absorber has turned blue . . . 😕

-

AuthorPosts

- You must be logged in to reply to this topic.