Home › Forum › Ask A Member › 6r74c missing parts ??

- This topic has 34 replies, 6 voices, and was last updated 6 years, 4 months ago by

fisherman6.

fisherman6.

-

AuthorPosts

-

November 16, 2017 at 3:19 pm #8679

the drive shaft on my 6hp is missing parts 1-6 just above the cross pin on top of the shaft

are they stuck up in the powerhead or should they have come out with the drive shaft 🙁 ????

those parts are more expensive than the whole motor 😯

http://www.marineengine.com/parts/johns … n=Gearcase

Joining AOMCI has priviledges 🙂

November 16, 2017 at 3:44 pm #67490They are likely up under the powerhead. The cross pin has a notch to travel through up in the exhaust cavity, but leaves the spring/cup/seal bits in place. Best to pull the powerhead and inspect the upper main seal bits, as failure of the o-ring or the gasket can cause issues…

November 16, 2017 at 4:00 pm #67492phew… that sounds encouraging.. parts resting the the ph

as to pulling the head ….i’ll take a chance on it. this engine innards (lower exhaust) are so clean I doubt this engine ran much. it was likely stored for years . I will send my camera probe for a closer look up it’s…..rear end 😯

thermostat has never been pulled ( bolt paint untouched)

i’ll soak it for a few day/weeks to try and unstuck it

if not the cyl head willl be removed to access the pistons faces for my peg/hammer arguments which finally convinced my 9.5hp

thanks for reply

Joining AOMCI has priviledges 🙂

November 16, 2017 at 4:42 pm #67494Those parts are captured below the powerhead. I can’t remember what year, but in the late 60s, the 6hps were changed to a split shift rod with the coupler which eliminates the need to pull the powerhead for an impeller change / lower unit service. The lower crankshaft seal components remain captured, but the roll pin must pass thru a slot. This makes alignment of everything when it goes back together somewhat challenging. It has also made for a lot of broken pins.

Being that this engine has had little apparent use, as long as care is exercised upon reassembly, it us a reasonable assumption in my opinion that the seal components are OK and will be serviceable for some time to come. It is often just as easy to pull the powerhead even on these motors for service, however, and it reduces the likelihood of damaging the carbon seal upon reassembly. It also give the opportunity to inspect the components. The only downside is that you will probably need to replace the powerhead base gasket. I have done it both ways, but on a motor I don’t know the history of, I usually pull the powerhead and replace the O-ring and the seal gasket just so I know I’m starting with new parts. I’m not suggesting this is necessary, it is just what I usually do for my own peace of mind when doing the mechanicals on one of these.

-BenOldJohnnyRude on YouTube

November 16, 2017 at 5:49 pm #67495November 16, 2017 at 6:16 pm #67496quote Mumbles:The infamous slot.Thank you for posting that Mumbles. I didn’t have a picture of it.

-BenOldJohnnyRude on YouTube

November 17, 2017 at 3:42 am #67524Ben thanks for the insight. I have pulled the head on older versions to change the impeller and found it a no big issue really . In this case I will proceed with caution on reassembly of the L.U.

for now in need to test for compression of course after I loosen it up, change the coils & wires adjust the points check for sparks , clean the carb and pop in an impeller then wait for the winter ice to melt in April 😥

No snow yet in Montreal but St-Catherine day in coming (nov 25th) all hell breaks loose around that date for some reason .

At least I can watch the beach in Daytona with the web cam 😀

http://www.volusia.org/news/daytona.stml

Joining AOMCI has priviledges 🙂

November 17, 2017 at 10:39 am #67529If the power head is stuck, I would not even think twice about pulling it apart. ANY rust on the rod bearings will result in a very short service life if you do manage to get it unstuck. Well worth the effort, as they are great little motors.

November 17, 2017 at 1:56 pm #67535can i peek inside if I remove the reeds ?? 🙄 I could scope around to check things out. I never took a motor apart … I guess there is always a first

Joining AOMCI has priviledges 🙂

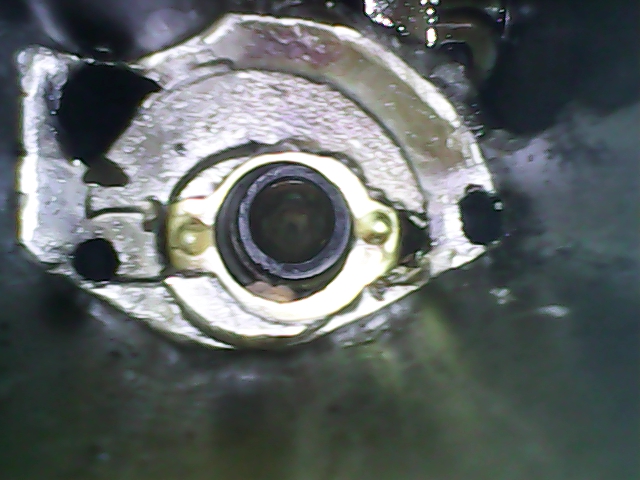

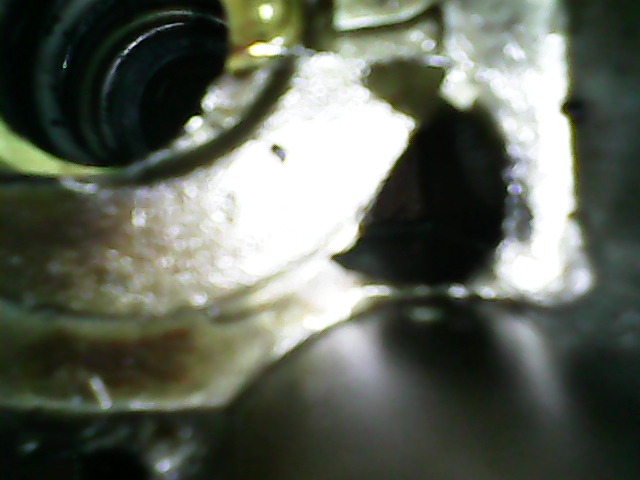

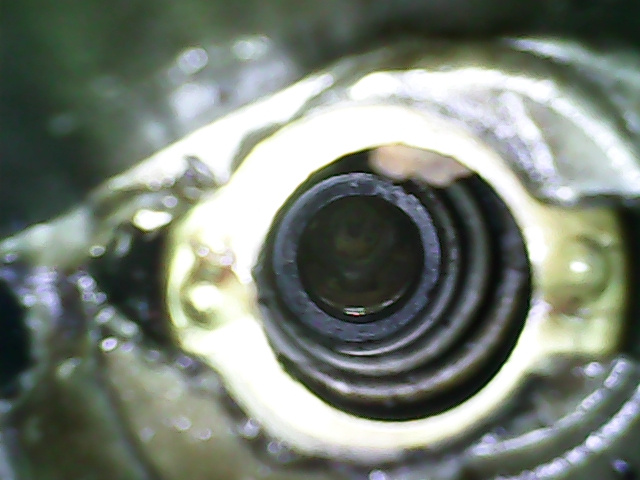

November 17, 2017 at 5:47 pm #67550here are a few pics …. the suspected missing parts are indeed up in there 😀

on picture Spline-2 right side of base is a ragged hole is that a casting flaw ?

( "6hp splines picture" ……is oriented the wrong way the ragged hole is really on the right side looking up 🙄

as you can see the area is vey clean looking as is the whole exhaust cavity

Joining AOMCI has priviledges 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.