Home › Forum › Ask A Member › 1957 Evinrude Big Twin 35 Skeg interferes with gears.

- This topic has 69 replies, 12 voices, and was last updated 3 years, 5 months ago by

boscovius.

boscovius.

-

AuthorPosts

-

January 17, 2022 at 11:12 am #252997

Fella’s,

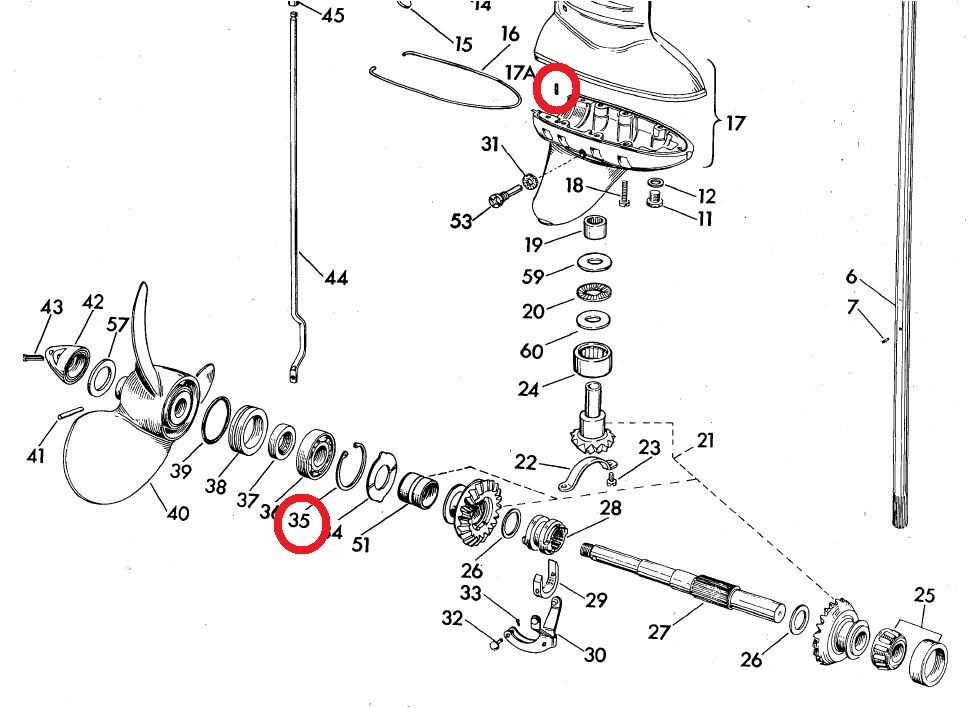

I’ve got a spare lower unit for my 35 Big Twin that I’m refurbishing. I bought it used on Ebay. Turns out it had a crack in the skeg that was only apparent under pressure test with some soapy water applied. I found another skeg online that looked like it was in nearly mint condition. Bought that and went to put it on and discovered that by the time I have the spaghetti seal and everything in place, by the time I’ve got it tightened down to where it needs to be I am no longer able to turn the shaft. If I back the screws out I can turn it again. So the obvious explanation would be that there is something about this casting that off.

To investigate this I’m going to invert the lower unit, remove the skeg, clean everything up and then place some old fashioned carbon paper over the innards of the lower unit with the carbon side up and then apply the skeg. I think by the time I’ve gotten it all tightened down, some of the carbon should become impressed onto the skeg and inform me of where the interference is. Then I would remove a bit of material with my dremel tool and a grinding bit.

If anyone wants to offer any cautionary tales of advice, I’m all ears. At least, like I said, this is a spare lower. I’ve got a good one ready to go. Just want to have both in operating condition. I’ll post a picture of what the carbon shows me when I get that far.

Thanks.

P.S. I had considered attempting to repair the crack in that other skeg with one of those alumiweld rods. Or maybe I should just give that to a guy with a TIG welder?

January 17, 2022 at 11:39 am #252998Well, as we know, those gearcase halves are made as a set, and are not interchangeable. Even though guys seem to do it all the time. One thing on a small engine, but another thing on a larger bigtwin gearcase.

I guess I would clean up the old cracked skeg and install it dry/so seal, etc. If the prop shaft rotates easily now, then you have your answer.. I don’t think there are any other pins (like in the smaller gearcases) that could have been pushed into the housing causing this binding. There is one pin that must be lined up on the rear seal housing though.

I’m assuming you replaced the rear seal, but seems doubtful that is an issue. Are you trying to rotate the assembly with the pinion and driveshaft installed? If so, perhaps there is an issue with those fits.

So again, if you are trying to rotate the prop shaft with the pinion/driveshaft installed, you may want to remove the pinion, reassemble and try again. Did you replace any of the pinion bearings? If so, perhaps there is an issue with fit/installation.

But, if you are trying to rotate without the pinion and things still bind, this would probably indicate that that skeg you found does not fit properly. Again, these housings are a unique fit and are not meant to be interchanged, just like crankcase halves.

January 17, 2022 at 12:19 pm #252999In addition to the locating pin on the rear seal housing, there is also the retaining ring behind the rear thrust washer. The retaining ring has to be lined up correctly in the groove in both the lower and upper half of the gearcase housing for everything to turn properly.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."January 17, 2022 at 1:24 pm #253000There might be something different with the rear dowel pin fitting into the seal housing. Double check the fit and alignment and also try tapping on the end of the prop shaft while tightening the screws. Doing this will help to seat the front bearing. The retaining snap ring should have a slight taper on one side and you should also see the groove for it has a matching taper. It only goes on one way.

Doing a dry fit before applying any sealer is always a good idea so you can fix any issues first.

January 17, 2022 at 2:35 pm #253004Mumbles adds a good clarification on the orientation of the retaining ring. When I noted it had to be lined up correctly, I should have made it clear that it could only go in one way. Thanks to Mumbles for this clarification.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."January 17, 2022 at 3:12 pm #253005Also possible, ? Somebody in the past may have well lapped down the skeg

and / or the upper housing’s mating surfaces a little too much, causing

the binding.

Prepare to be boarded!

January 17, 2022 at 3:15 pm #253006Thank you for all the replies fellas.

The last time I had it apart I did dry fit everything up and everything seemed fine. Nice tight fit to the top of the gearcase. “new” pinion pin in place with the rear seal housing fitting flush. Retaining ring in position just as in the diagram. (I have the parts diagram book here at home and that is indeed a treasure.) All that looked good. I can tighten the skeg down to the point where there is maybe a sixteeth of an inch or less to go and that’s when things start to bind. To clarify, I am turning the crankshaft by hand, I’d have to take it apart again to verify, but I am quite certain the new skeg has the same part number as the old one. Whether that is here nor there as far as castings are concerned, I have no idea. I’ll come back with pictures after I try out the carbon paper experiment.

January 17, 2022 at 6:06 pm #253009Looking back on what Mumbles said about the “Retaining Snap Ring”. I was unaware of this, and maybe I just got lucky because everything did go back together. But is this something that could cause an interference? I’ll take a closer look at it when I have it apart next time.

January 17, 2022 at 7:57 pm #253011OK, so you replaced the pinion as well. Did you replace that pinion bearing with all the big needles that fall out? If so, perhaps you did not install the bearing race properly. Are you sure the pinion is the correct part number? So, you can only tighten the skeg screws partially before the unit binds while rotating the driveshaft by hand, correct?

So, I guess there are a few possible issues. Perhaps there is a problem with the pinion/fwd/reverse gear fit/lash. If so, it is best to remove the pinion and reassemble the prop shaft/gears/skeg without the pinion. If this solves the problem, then it would appear there is an issue with pinion/bearing/fit.

If the issue still persists without the pinion, then I would reassemble without the pinion using the old skeg. If the unit rotates freely now, then the replacement skeg you are using isn’t fitting properly. Don’t get confused with numbers you might find on these castings, they are not necessarily part numbers, they might be engineering “casting numbers” which should not be confused without actual part numbers.

January 18, 2022 at 11:39 am #253015I had a similar problem a while back on a RDL-19 Johnson 35 hp, took that thing apart, put it back together, I forgot how many times, tried another gear case , same problem, took it apart again and moved the lower shift rod 180 degrees, to the other side of gearcase, installed shaft and gears in gearcase, fell rite together, tightened up fine & shifted great. That was problem lower shift shaft rubbing on gearcase. I used other gearcases before never had a problem. What I do now is take a picture of gearcase or whatever it is you are taking apart for reference down the line. Parts always get mixed up when washing- cleaning.

Gene.

-

AuthorPosts

- You must be logged in to reply to this topic.